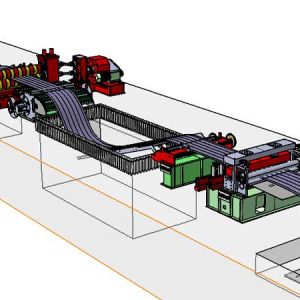

Slitting Line :

The LOTOS Slitting Line is an advanced system designed to uncoil wide metal coils, slit them into narrower strips with precise widths, and then rewind them into separate coils. These lines are suitable for a wide range of materials, including stainless steel, galvanized steel (GI), carbon steel, aluminum, copper, hot rolled steel, and cold rolled steel. The system is composed of key components such as the uncoiler, press and pinch, slitter, edge scrap winder, tension control unit, and recoiler—all operating fully automatically with high accuracy and efficiency. To ensure long-term reliability and stable performance, LOTOS slitting lines are equipped with electrical and control components from internationally recognized brands such as Siemens, Omron, and Schneider. Slitting speed can be customized based on the production needs, with standard models available in a range of 30 to 180 meters per minute. Lines with speeds exceeding 80 m/min are categorized as high-speed slitting lines. This flexibility in design allows the system to be optimized for various material types, production volumes, and specific technical requirements. Each LOTOS slitting line can be fully customized in terms of size, speed, blade configuration, and control systems to meet the precise demands of different industrial applications.

CUT-TO-LENGTH LINE:

Cut-to-length technology enables the precise cross-cutting of metal coils into flat sheets with defined lengths and geometries. These sheets are then stacked and prepared for further processing or direct use. At Wuxi Lotos Roll Forming Machine Co.,LTD , our cut-to-length lines are designed for efficiency, accuracy, and adaptability across a wide range of metals and coil formats, including hot-rolled steel, cold-rolled steel, galvanized steel (GI, GL), pre-painted steel (PPGI/PPGL), stainless steel, carbon steel, aluminum, and copper. Depending on production needs, our systems can be equipped with either stationary shears (stop-and-go operation) or flying shears for continuous high-speed processing, combined with optimized stacking solutions for seamless material handling. Each line configuration is tailored to specific production goals, taking into account factors such as material type, sheet thickness, output dimensions, and desired throughput. All LOTOS lines are fitted with precision leveling systems to ensure flatness and surface integrity.

The best products of our company

Latest news from lotosslitting

CUSTOMERS ABOUT US

After extensive research, we chose the Trapezoidal Shear Cut To Length Line from Lotus Slitting. This machine can be easily adjusted to any required size, and the cut quality is outstanding. Their 10-year warranty is a clear sign of their confidence in their products. We are very satisfied with our choice.

For our aluminum cutting project, we purchased an Aluminium Slitting Line from Lotus Slitting. The machine works perfectly and exactly meets our needs. Most importantly, the 10-year warranty and strong after-sales service allow us to use it with confidence.

If you’re looking for technical specifications, project consultation, customized line design, or manufacturing solutions for metal coil slitting or cut-to-length systems, our engineering team is ready to assist you.

Please fill out the form on this page, and one of our technical experts will get back to you shortly.