Heavy Gauge Slitting Line

The Heavy Gauge Slitting Line is designed for slitting high thickness, high strength metal coils and falls under the category of heavy-duty sheet preparation equipment. This system utilizes a reinforced mechanical structure, a sturdy chassis, high power drives, and hardened blades to ensure precise and uniform slitting of thick sheets without compromising surface quality or cutting parallelism.The performance of this line is stable under harsh and continuous working conditions, making it ideal for heavy industries such as steelmaking, heavy equipment manufacturing, automotive production, rail transport, and industrial metal frameworks.

Steel Slitting Line

The process begins with the uncoiling of the metal coil by the uncoiler. Next, the sheet passes through the leveling unit to eliminate internal stresses and achieve a smooth, uniform surface. After leveling, the sheet enters the slitting unit, where precision blades cut the sheet into narrow strips with a cutting tolerance of ±0.05 mm. This step is performed with high accuracy to avoid any cutting errors or warping.

The cut strips are then drawn through guide systems and fed into the recoiler, where they are rolled back into narrower coils. Finally, the output coils are prepared for packaging and shipping. This fully automatic line is controlled by a PLC system and industrial user interface, enabling easy adjustments, precise monitoring, and rapid execution of the slitting operations.

Precision Slitting Line Machine

The heavy duty Slitting line is designed with a reinforced mechanical structure and equipped with state of the art technology to efficiently cut high thickness steel sheets. Engineered for precision and stability, this system maintains consistent performance even under demanding industrial conditions.

With integrated automation and advanced PLC control systems, it offers increased productivity, reduced cutting errors, and enhanced product quality making it an optimal solution for high capacity steel processing plants and heavy equipment manufacturers.

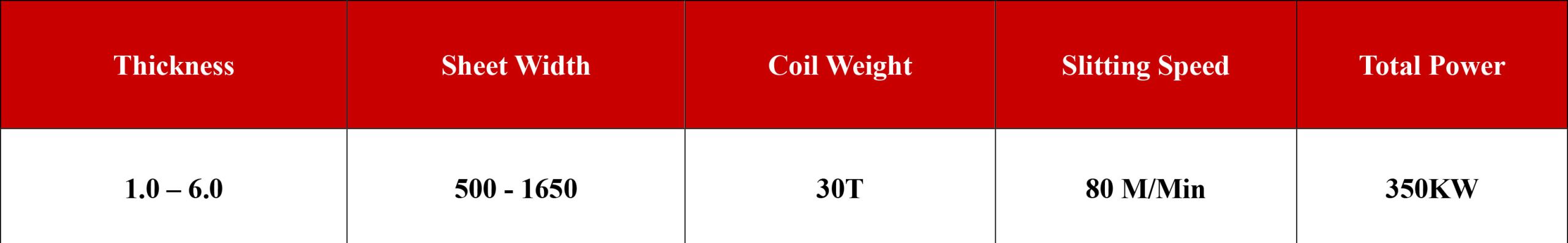

Capable of processing steel sheets with thicknesses from 1.0 mm to 12.0 mm and widths ranging from 500 mm to 1650 mm, the line operates at high cutting speeds while ensuring dimensional accuracy. This cut-to-length solution is ideal for manufacturers in the steel industry, metal service centers, and heavy fabrication sectors looking for reliable and efficient coil processing equipment.

Quastion :

1. What is the difference between a slitting line and a cut-to-length line, and which one is more suitable for our production needs?

Answer:

A slitting line cuts metal coils into narrower strips and recoils them, which is ideal for tube production, roll forming, and other applications requiring narrow coils.

A cut-to-length line, on the other hand, cuts coils into flat sheets of specific lengths, which is suitable for sheet fabrication, stamping, or structural components.

The right choice depends on your final product type and production process.

2. What kind of after-sales services and warranty do you offer for these machines?

Answer:

We offer a 12-month warranty covering mechanical and electrical components. Our after-sales services include on-site installation, operator training, spare parts supply, technical support, and remote or in-person maintenance assistance throughout the machine’s operational life.

3. What types of metals are compatible with this production line?

Answer:

Our lines are compatible with a wide range of metals, including carbon steel, stainless steel, galvanized steel, aluminum, and some copper or brass alloys. The specific materials depend on the blade configuration and mechanical setup of the line.

4. What infrastructure is required in the factory to install and operate this line?

Answer:

The facility must have sufficient space for the full line layout, three-phase industrial power (e.g., 350 kW for thin gauge), an overhead crane for coil handling, proper foundation for machine stability, and adequate ventilation. We can provide a detailed layout and utility requirements based on your site.

5. If our production needs change in the future, is it possible to upgrade the line?

Answer:

Yes, many components such as blades, drives, and control systems can be upgraded to meet new specifications. We also offer the option to add new units or retrofit existing ones, depending on your new production requirements. A technical evaluation is recommended for tailored solutions.