Medium Gauge Slitting Line

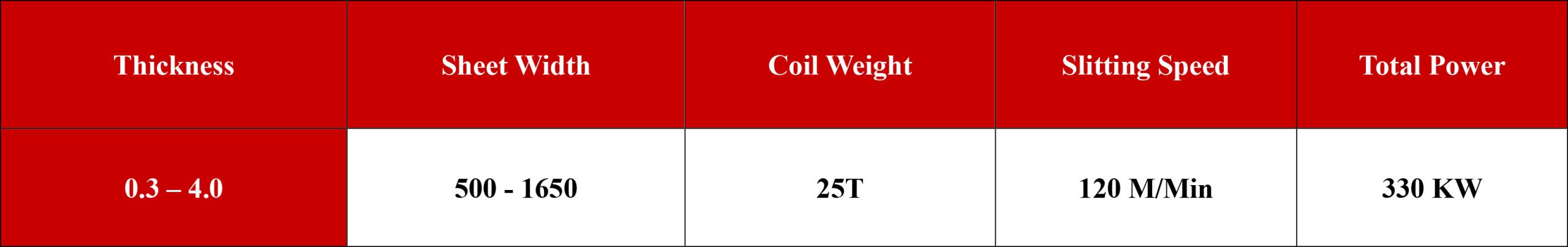

The Medium Gauge Slitting Line is a specialized machine for slitting metal coils and converting them into precisely sized and uniform strips. With its precise design, the use of high quality blades, and an advanced control system, this line ensures that sheets are cut cleanly and consistently without any damage or surface quality degradation. This line has widespread applications in various industries, including profile production, component manufacturing, metal equipment, and light to medium structural applications.

Medium Guage Coil Slitting Line

The process begins with the uncoiling of the coil by the Uncoiler. The sheet then passes through the Leveling Unit, where internal stresses are eliminated, and a uniform surface is achieved.Next, the sheet enters the Slitting Unit, where it is precisely slitted into strips of specified widths with a cutting tolerance of ±0.05 mm using high precision blades. This stage is carried out with utmost care to prevent any cutting errors or warping.

The slitted strips are then guided by the guiding systems, stretched, and fed into the Recoiler section, where they are re wound into narrower coils. At the end of the process, the output coils are prepared for packaging and transportation. This line is fully automated and, with the help of a PLC control system and an industrial user interface, allows for easy adjustment, precise monitoring, and quick execution of the slitting operation.

Slitting lines for medium gauge

The Medium Gauge Slitting Line is engineered to deliver automatic operation, high precision cutting, and optimal handling of metal coils. Designed to slit medium thickness metal sheets with accuracy and speed, this line is a reliable solution for steel processing plants, automotive parts manufacturing, and metal fabrication industries.

By combining cutting quality, production speed, and ease of setup, the system enables manufacturers to streamline production workflows and reduce downtime. Its advanced control system ensures repeatability and consistency, making it an excellent investment for companies seeking performance and reliability in coil slitting operations.

Quastion :

1. How does the Medium Gauge Slitting Line ensure high-precision cutting for medium-thickness metal sheets?

Answer:

The Medium Gauge Slitting Line ensures high-precision cutting by utilizing high-quality blades, an advanced control system, and a precise design. This setup guarantees that the sheets are cut cleanly and consistently, without any surface damage or quality degradation, maintaining high accuracy during the cutting process.

2. Is this slitting line fully automated, and are the settings easy to adjust?

Answer:

Yes, the Medium Gauge Slitting Line is fully automated and uses a PLC control system with an industrial user interface. This allows for easy adjustments to the settings, precise monitoring, and quick execution of the slitting operation, providing operators with an efficient and streamlined user experience.

3. What benefits does the Medium Gauge Slitting Line provide to manufacturers?

Answer:

The Medium Gauge Slitting Line provides several key benefits to manufacturers, including high cutting quality, production speed, and ease of setup. It helps optimize production workflows, reduce downtime, and maintain consistent performance with repeatable precision, ultimately improving product quality and reducing material waste.

4. Can this slitting line operate under harsh and continuous working conditions?

Answer:

Yes, the Medium Gauge Slitting Line is designed to operate efficiently under harsh and continuous working conditions. With its robust construction and advanced technology, it is well-suited for demanding industrial environments, ensuring stable performance even during long periods of high-intensity operation.