How Are Blanking Lines Used in Metal Processing?

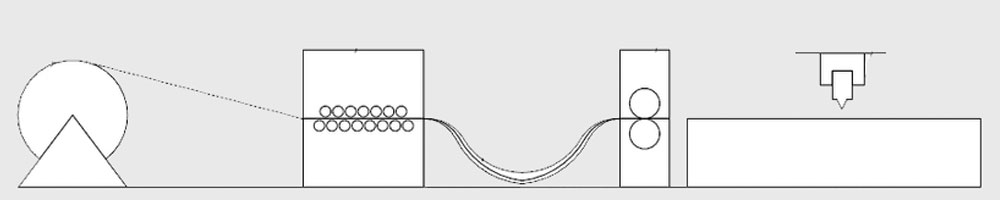

Blanking lines play a crucial role in metal processing by transforming large coils or sheets of metal into smaller, precise shapes or “blanks” that serve as raw materials for manufacturing various products.Here’s a breakdown of how blanking lines are used in metal processing:

1. Material Loading

- Input Material: Metal coils or sheets (e.g., steel, aluminum, copper).

- The coil is mounted on a decoiler, which unrolls it to feed into the machine.

2. Straightening and Flattening

- The material passes through a leveler or straightener to remove any coil memory or curvature.

- This ensures flat and uniform material for accurate processing.

3. Feeding and Alignment

- A feeder system pushes the metal through the blanking press or cutting section.

- Precision alignment mechanisms ensure the material is correctly positioned for consistent cuts.

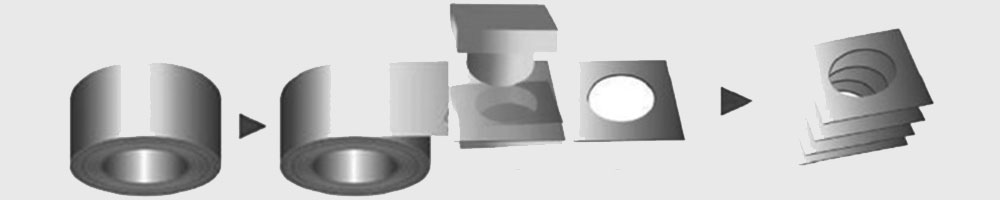

4. Cutting or Stamping

- The blanking press uses dies or cutting tools to cut the metal into specific shapes or sizes.

- Cut to length: Produces flat sheets of desired dimensions.

- Blanking dies: Stamp out predefined shapes, such as circles, rectangles, or custom designs.

- High speed operations allow for mass production.

5. Sorting and Stacking

- The blanks are automatically sorted and stacked for easy handling and transport.

- Scrap or leftover material (trim) is directed to a scrap handling system for recycling.

6. Automation and Quality Control

- Modern blanking lines incorporate automation and sensors to monitor dimensions, quality, and efficiency.

- Any defective blanks are identified and removed.

Applications of Blanking Lines

- Automotive Industry:Producing body panels, doors, and other stamped components.

- Appliances:Parts for refrigerators, ovens, and washing machines.

- Electrical Industry: transformer laminations, motor parts, and enclosures.

- Construction:Roofing sheets, beams, and structural components.

- Aerospace:Precision blanks for high-strength components.

Advantages of Using Blanking Lines

- High Precision: Ensures exact dimensions and consistent quality.

- Efficiency: High-speed processing enables mass production.

- Versatility: Can handle various metals and thicknesses.

- Material Utilization: Minimizes waste by optimizing the layout of blanks on the sheet.

1. Fine Blanking Lines

Fine Blanking Line is a specialized blanking process designed for high precision and clean edged parts.This technique is widely used when parts require tight tolerances and smooth edges.

- Triple Action Press: Utilizes three forces (blanking force, counterforce, and clamping force) to achieve high precision and minimize distortion.

- Precise Die Clearance: The gap between the punch and die is extremely small, ensuring clean shearing without tearing.

- Smooth and Burr-Free Edges: Eliminates secondary finishing processes.

- Materials: Often used with softer metals like aluminum or specific alloys for automotive or electronics industries.

Applications:

- Automotive components (gears, levers, brackets).

- Watch and precision instrument parts.

- Electrical connectors and switches.

Advantages:

- Superior surface quality and precision.

- Allows for high-strength, thin materials to be processed efficiently.

- Ideal for high volume, detailed part production.

2. Progressive Blanking Lines

Progressive blanking lines combine multiple operations in continuous processes, such as cutting, punching, bending, and sometimes forming.

- Multiple Dies in One Tool: The material moves through a series of stations, each performing a specific task.

- High Speed Processing: Ideal for mass production of complex parts.

- Continuous Material Feed: The strip material moves step by step, and blanks are separated at the end.

Applications:

- Automotive parts (suspension components, brackets).

- Appliance hardware (handles, hinges).

- Consumer goods (cutlery, fasteners).

Advantages:

- Minimizes handling and reduces processing time.

- Capable of creating intricate parts with several operations in a single pass.

- Cost effective for high-volume runs.

Comparison Between Fine and Progressive Blanking

| Feature | Fine Blanking | Progressive Blanking |

|---|---|---|

| Precision | Very high | Moderate to high |

| Surface Finish | Clean, burr-free | May require secondary processing |

| Complexity of Parts | High, ideal for intricate designs | High, but with simpler shapes |

| Speed | Moderate | High |

| Applications | High-precision components | Complex parts with multiple operations |

While both blanking and CTL (Cut-to-Length) lines handle metal coils, blanking lines create shaped pieces, whereas CTL lines focus on cutting sheets to specified lengths.