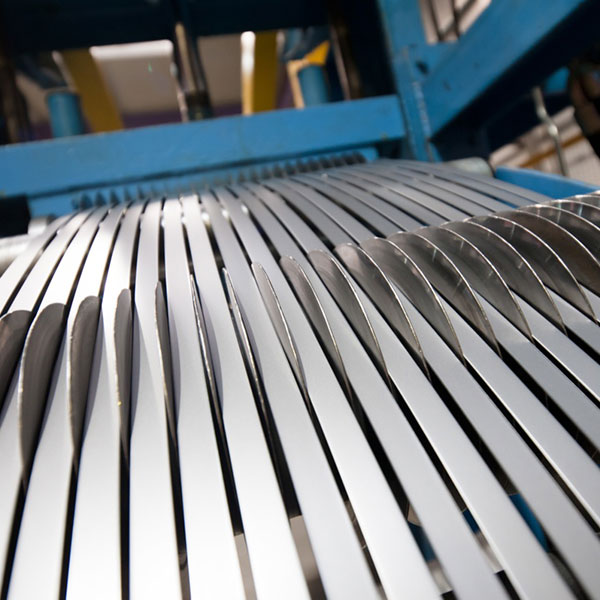

Aluminum strip Slitting Machine

The Aluminium Slitting line operates with precision and efficiency, ensuring that each

coil is cut to the exact specifications required by the customer. This level of accuracy is crucial

for maintaining the quality and integrity of the aluminum coils throughout the production

process. Not only does the Aluminum Slitting line offer exceptional precision, but it also boasts

an impressive speed, allowing manufacturers tomeet high production demands without compromising

on quality.

Aluminium Slitting Line Technical Specification

- Material Specifications:

- Material Type: Primarily aluminum coils of various alloys

(e.g., AA1050, AA3003, AA5052). - Material Thickness: The range of thicknesses the machine can handle,

typically from 0.1 mm to 4.0 mm. - Coil Width: Range of widths the machine can process, typically from

100 mm to 2000 mm.

- Material Type: Primarily aluminum coils of various alloys

- Slitting Parameters:

- Number of Slitting Blades: Specifies how many blades are used

simultaneously for cutting. - Minimum Strip Width: The narrowest width of the strips that can be produced,

typically down to 10 mm or less. - Tolerance: Precision in maintaining strip width consistency across the coil length,

often specified within ± 0.1 mm to ± 0.5 mm.

- Number of Slitting Blades: Specifies how many blades are used

- Line Speed and Capacity:

- Line Speed: The operating speed of the slitting line, ranging from 50 meters

per minute (m/min) to 300 m/min. - Maximum Coil Weight: The maximum weight of the coil that the line can handle,

typically up to 20 tons. - Maximum Coil Outer Diameter (OD): The maximum diameter of the coil that can

be processed, often up to 2000 mm.

- Line Speed: The operating speed of the slitting line, ranging from 50 meters

- Feeding and Uncoiling System:

- Coil Car: Equipment for loading and unloading coils onto the slitting line.

- Decoiler: Device for unwinding the coil, usually with hydraulic or motorized options.

- Loop Control: System to maintain proper tension and material flow during operation.

- Slitting and Recoiling System:

- Slitting Heads: Units equipped with precision slitting knives or rotary shear

for clean, accurate cuts. - Separators: Mechanism to separate and guide the individual strips after slitting.

- Recoiler: Device for rewinding the slit strips into coils of specified dimensions

with tight tolerance

- Slitting Heads: Units equipped with precision slitting knives or rotary shear