WHAT IS THE SLITTING VS CUT TO LENGTH PROCESS?

Both of these machines have their own unique set of features and functionalities that make them stand out. So, let’s dive right in and explore the wonderful world of slitting lines and cut to length machines.

Fingrst things first, let’s talk about what a slitting line is. A slitting line is a machine that use to cut wide coils of steel into narrower strips. It is perfect for industries that require different widths of steel strips for their production processes.

The slitting line works by feeding the coil through a set of rotating circular blades that make precise cuts along the length of the coil. The strips are then wound onto separate recoilers, ready to be used for various applications. With a slitting line, you can easily obtain multiple narrower strips from a single wide coil, making it a highly efficient and cost-effective solution.

On the other hand, a cut to length machine, as the name suggests, use to cut steel coils into specific lengths. This machine is ideal for industries that require standard-sized sheets or plates for their manufacturing processes. The cut-to-length machine works by feeding the coil through a straightening unit that removes any deformations in the material. Then, using a guillotine shear or rotary shear, the machine cuts the coil into precise lengths as per the required specifications.

These cut pieces are then stacked or transferred onto a conveyor belt for further processing. With a cut to length machine, you can easily obtain accurately sized sheets or plates with minimal wastage.

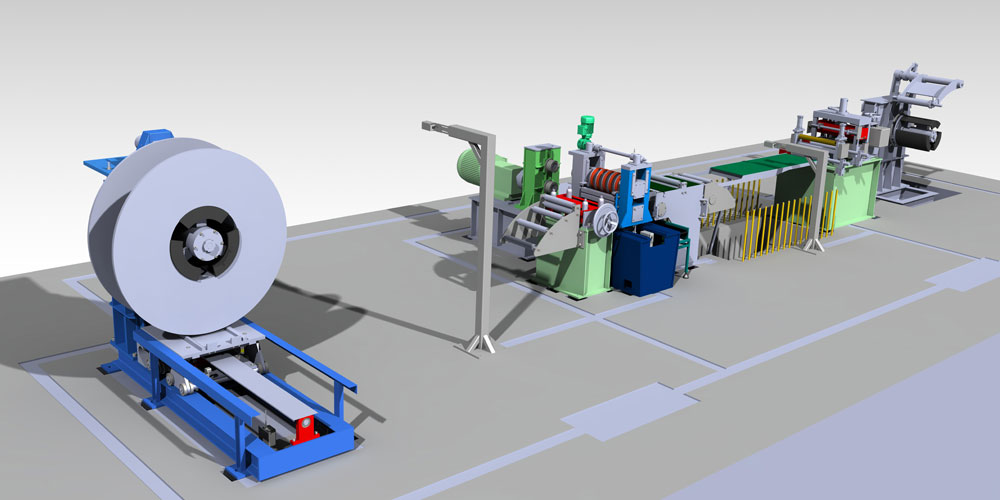

Coil Slitting & Cut to Length Machine

In the steel processing industry, two essential types of equipment are the slitting line and the cut to length (CTL) machine. While both machines use to process steel coils, they serve different purposes and design to achieve distinct outputs. Understanding their differences is crucial for manufacturers to select the right equipment for their specific production needs.

Difference between coil slitting machine and cut to length line

The primary function of a slitting line is to cut a wide steel coil into multiple narrower strips. This process is vital for industries requiring various widths of steel strips for their production lines. In contrast, a cut to length machine design to cut steel coils into flat sheets or plates of specific lengths, which are used in applications that demand standardized dimensions and precision.

A slitting line operates by feeding a wide coil through a series of rotary slitting knives, which cut the coil along its length into narrower strips. These strips are then wound onto separate recoilers for easy handling and transport. On the other hand, a cut to length machine feeds the coil through a straightening unit to remove deformations, followed by a shear that cuts the coil into specified lengths, ensuring the flatness and dimensional accuracy of the final product.

Slitting lines and cut-to-length (CTL) lines

Slitting lines and cut-to-length (CTL) lines are both used in metal processing to prepare coils of metal for use in manufacturing, but they serve different purposes and produce different outputs. Here’s a breakdown of the differences:

1. Purpose

- Slitting Line: A slitting line is used to cut a wide coil of metal into narrower coils. The coil is fed through a series of rotating knives that slit the material into narrower strips of the desired width.

- Cut-to-Length Line (CTL): A CTL line is designed to cut a metal coil into flat sheets or plates of a specified length. The coil is uncoiled, leveled to remove any curvature, and then cut to a specific length.

2. Output

- coil.

- Cut-to-Length Line: Produces flat sh

- Slitting Line: Produces multiple narrower coils (slit coils) from one wider coil.

- Cut-to-Length Line: Produces flat sheets or plates of specific lengthS

3. Typical Applications

- Slitting Line: Used when manufacturing processes require narrower strips of metal, such as in the production of steel pipes, automotive parts, or roll-formed products.

- Cut-to-Length Line: Used when flat sheets are needed for products like automotive body panels, appliances, metal enclosures, or construction materials.

4. Equipment Components

- Slitting Line: Includes an uncoiler, a slitter (with rotating knives), tensioning system, a recoiler, and sometimes an edge trimming system.

- Cut-to-Length Line: Includes an uncoiler, a leveler (to flatten the sheet), a feeder (to move the material forward), a shear or cutter, and a stacking or packaging system.

Difference between slitting and cutting machine

- 5. Process

Difference between slitting and cutting machine

- 5. Process

- Slitting Line:

The narrower strips are then rewound into smaller coils.

- The coil is uncoiled.The material is fed through the slitter, which cuts the coil into narrower strips.

- Cut to Length Line:

The coil is uncoiled.

The material is leveled to remove any coil set or curvature.

The leveled material is fed through to the shear or cutter, where it is cut to the desired length.

The cut sheets are then stacked or packaged.

6. Material Handling

- Slitting Line: Focuses on precision cutting of material width while managing multiple narrow strips.

- Cut to Length Line: Focuses on precision cutting of material length, ensuring flatness and proper stacking of sheets.

In summary, while both processes start with a metal coil, the slitting line focuses on producing narrower coils by cutting the width, whereas the CTL line focuses on producing flat sheets of specific lengths.

- Slitting Line:

6. Material Handling

- Slitting Line: Focuses on precision cutting of material width while managing multiple narrow strips.

- Cut to Length Line: Focuses on precision cutting of material length, ensuring flatness and proper stacking of sheets.

In summary, while both processes start with a metal coil, the slitting line focuses on producing narrower coils by cutting the width, whereas the CTL line focuses on producing flat sheets of specific lengths.

- 5. Process