What is the Cut to Length Machine Process?

The cut-to-length machine process involves uncoiling, leveling, and cutting metal coils into precise sheet lengths. This automated process enhances production efficiency by ensuring uniform sheet dimensions and reducing material waste. Cut to length (CTL) lines are used across industries requiring flat, high-quality metal sheets for various applications

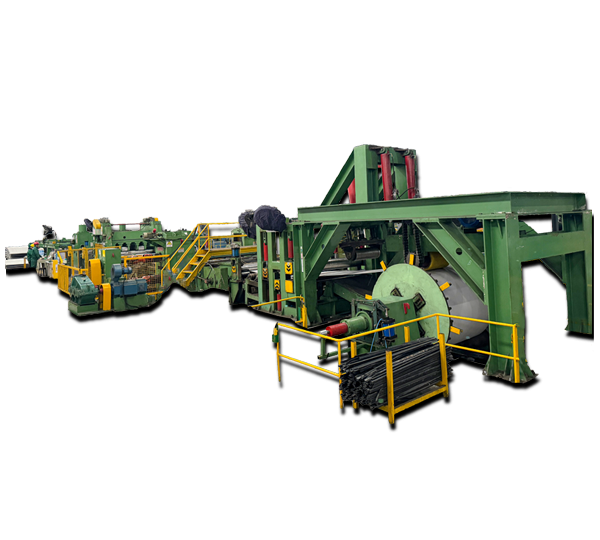

CTL lines

A heavy duty cut to length line is designed to process thick and high strength metal coils. This type of CTL line is ideal for handling materials like carbon steel and structural steel, commonly used in shipbuilding, bridge construction, and heavy machinery manufacturing. With robust components and powerful leveling mechanisms, these lines ensure durability and high performance.

Steel Cut To Length Services

Steel cut to length services provide customized sheet lengths tailored to specific manufacturing requirements. These services help industries such as automotive, construction, and appliance manufacturing by delivering flat, precisely cut steel sheets. Advanced CTL lines ensure accuracy in thickness and length while maintaining surface integrity.

Precision Cut to Length

Precision cut to length technology ensures tight tolerances and minimal deviation in sheet dimensions. High tech CTL lines use advanced sensors, servo driven feed systems, and computerized controls to achieve exceptional accuracy. This level of precision is essential for aerospace, electronics, and high end manufacturing industries where exact specifications are critical.

Cut to Length Material Processing

Cut to length material processing involves multiple steps, including decoiling, straightening, measuring, cutting, and stacking. Each step is meticulously controlled to ensure consistency and minimize material loss. Industries rely on CTL lines for producing sheets with accurate dimensions, smooth edges, and superior flatness, ready for fabrication and assembly.

Application of Cut to Length Line in Sheet Metal Industry

Cut to length lines play a vital role in the sheet metal industry by supplying high-quality sheets for various applications. From automotive panels and roofing sheets to HVAC components and home appliances, CTL lines contribute to efficient manufacturing. Their ability to process different materials with precision makes them an indispensable asset for sheet metal production.

Process of Cut to Length Line

A Cut to Length line is a specialized production system that begins by uncoiling large metal coils. The material then passes through a leveling unit to remove coil set and warping, ensuring flatness. Next, servo-driven feed systems measure and advance the metal to the desired length with high precision. The material is subsequently sheared into flat sheets using a hydraulic press. Finally, the finished sheets are stacked and collected for further processing or shipment.

Classification of Cut-to-Length Lines

These lines are suitable for processing materials such as Cold Rolled (CR), Hot Rolled (HR), Galvanized Iron (GI), Pre-Painted Galvanized Iron (PPGI), copper, aluminum, stainless steel, and other alloys in various thickness ranges. Depending on the application, CTL lines can be configured for thin (0.2–2 mm), medium (2–4 mm), or heavy gauge (5–25+ mm) materials. Each CLT is designed to suit specific production volumes, material types, and tolerance requirements, making them essential for efficient coil-to-sheet transformation.

Main Components of a Cut to Length Line:

- Hydraulic Entry Coil Car

Moves heavy metal coils into the decoiler smoothly and safely. - Hydraulic Decoiler

Unwinds metal coils under controlled tension for processing. - Pre-leveling Machine

Removes the initial coil set and prepares the strip for precise leveling. - Loop

Maintains consistent material tension and accommodates speed differences between units. - Side Guide Device

Ensures accurate lateral alignment of the metal strip during processing. - Precision Straightening Machine

Precisely flattens and straightens the strip to eliminate residual stress and curvature. - Cutter

Cuts the strip into sheets at exact lengths using hydraulic shear technology. - Transportation Table

Transfers cut sheets smoothly between processing stages. - Hydraulic Lifting Table

Adjusts the height of sheets for efficient stacking or transfer. - Pneumatic Stacker Device

Collects and stacks finished sheets automatically with controlled pressure. - Exit Coil Car

Moves finished coils or stacked sheets away from the processing area. - Pneumatic System

Provides compressed air power for actuating various pneumatic components. - Hydraulic System

Supplies hydraulic power for heavy-duty operations like decoiling and cutting. - Electrical System

Controls automation, motor drives, sensors, and safety devices throughout the line.