Cut to Length Lines

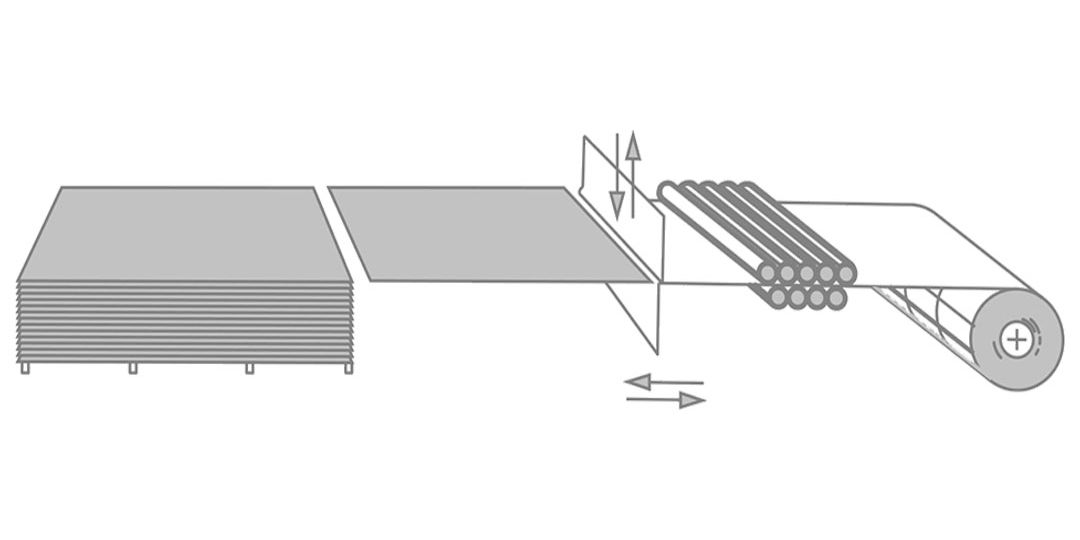

The transformation of coiled metal into flat, cut to size sheets is a critical operation in modern manufacturing. This process, known as coil to sheet

transformation, requires high precision equipment and advanced engineering.

LotosSlitting specializes in providing reliable solutions such as cut to length lines and CTL machines that ensure accurate, efficient, and high quality sheet

metal production. Below is an overview of the key stages and technologies involved in this essential industrial process.

Coil to Sheet Process

The coil to sheet process involves uncoiling large

rolls of metal, straightening the material, and cutting it into precise lengths. This conversion is vital for industries that require flat sheet metal

for further fabrication, such as automotive, construction, and appliance manufacturing. At the heart of this process is the integration of mechanical

accuracy and automation, which LotosSlitting delivers through state of the art machinery.

CTL Machine

The CTL machine (cut to length machine) automates the entire sheet cutting process, reducing labor costs while increasing consistency and productivity.

These machines are equipped with programmable controls that allow for quick adjustments based on material type and required sheet length

. LotosSlitting offers CTL machines tailored to different industrial needs, ensuring reliability and long term performance.

Applications of Cut to Length

Cut to length steel is widely used across sectors where precision and material quality are essential. Industries such as HVAC, shipbuilding, and infrastructure

rely on accurately cut sheets for efficient assembly and durability. LotosSlitting’s equipment produces steel sheets that

meet strict dimensional and surface standards, helping manufacturers meet their

project specifications with confidence.

CTL Technology

Using CTL technology brings significant advantages to metal processing operations. These include increased cutting accuracy, improved

material yield, reduced scrap, and enhanced operational speed. LotosSlitting’s CTL systems are built with durable components and intelligent

automation features that contribute to lower production costs and higher quality output.

Why Choose LotosSlitting for Coil Processing

LotosSlitting stands out as a trusted provider of coil processing equipment, including advanced cut to length lines and CTL machines.

With a focus on innovation, precision, and customer satisfaction, we deliver solutions that optimize production workflows and ensure

consistent product quality. Our machines are designed to handle a wide range of materials and coil sizes, making them a smart investment

for manufacturers worldwide.