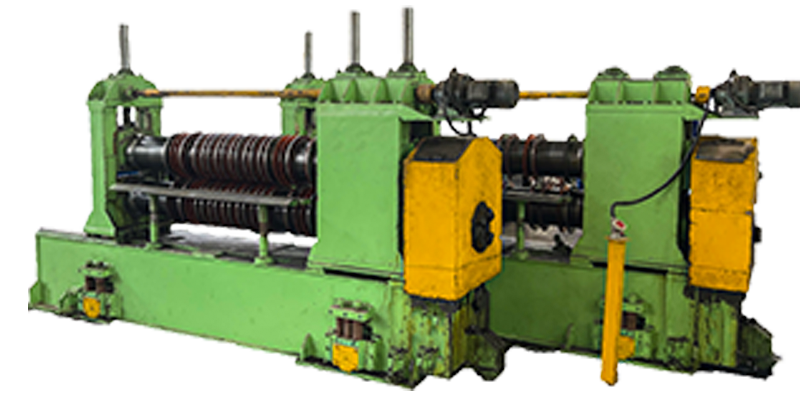

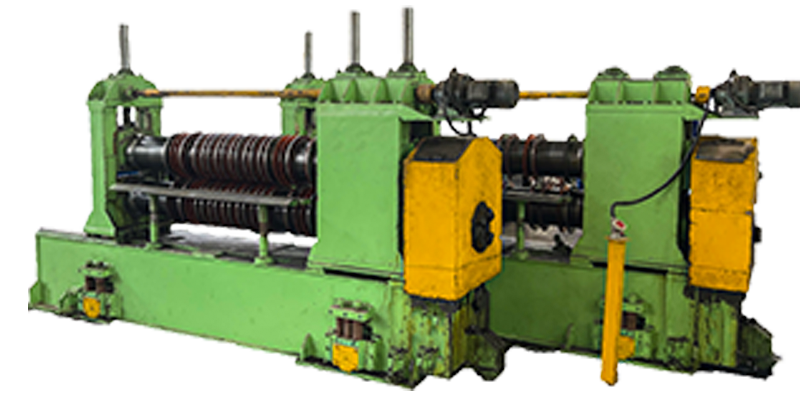

What Is a Double Slitter Head Coil Slitting Machine?

The Double Slitter Head Coil Slitting Machine is an advanced industrial solution designed for precision cutting of metal coils into narrower strips. Featuring two independent slitting heads, this machine enables simultaneous processing of multiple coil sections, significantly increasing productivity. Commonly used in metal processing industries, it handles materials like steel, aluminum, and copper with high accuracy. Its dual head configuration allows for greater flexibility in slit widths and reduces downtime during changeovers, making it ideal for high-volume production environments. Lotosslitting offers robust and reliable double slitter head models engineered for durability and performance.

Key Features of the Double Slitter Head Slitting Line

Lotosslitting’s Double Slitter Head Coil Slitting Machine is equipped with cutting edge features that ensure efficiency and precision. These include servo driven tension control, automatic knife positioning, and real-time width adjustment systems. The dual slitting heads operate independently, allowing different slit widths in a single run, which enhances operational versatility. Advanced PLC control systems provide user-friendly interfaces and seamless integration with upstream and downstream processes. Built with high-grade components, the machine ensures minimal maintenance and long-term reliability, making it a smart investment for metal fabricators.

Benefits of Using a Double Slitter Head Configuration

Choosing a Double Slitter Head Coil Slitting Machine offers numerous advantages over traditional single head models. The primary benefit is increased throughput two slitting heads mean double the output without doubling the footprint. This configuration reduces coil handling and setup time, improving overall operational efficiency. It also allows for better material utilization and reduced waste through optimized strip layouts. For manufacturers dealing with diverse product specifications, the ability to run multiple widths simultaneously translates into faster turnaround times and improved customer satisfaction all hallmarks of Lotosslitting’s innovative design philosophy.

Applications Across Industries

The Double Slitter Head Coil Slitting Machine is widely used across various industries, including automotive, construction, HVAC, and electrical manufacturing. Its ability to process a wide range of coil materials and thicknesses makes it indispensable for producing components like strips, blanks, and laminations. In the automotive sector, it supports the production of precision parts, while in construction, it aids in creating roofing and siding materials. Lotosslitting’s machines are tailored to meet industry specific standards, ensuring consistent quality and compliance, making them a trusted choice for global manufacturers.

Why Choose Lotosslitting for Your Slitting Needs?

Lotosslitting stands out as a leading manufacturer of Double Slitter Head Coil Slitting Machines, combining engineering excellence with customer focused innovation. Each machine is designed with precision, durability, and ease of operation in mind, backed by comprehensive technical support and after-sales service. The company uses advanced manufacturing techniques and rigorous quality control to deliver equipment that meets international standards. Whether you need a standard model or a fully customized slitting line, Lotosslitting provides

FAQ :

What is a Double Slitter Head Coil Slitting Machine?

A Double Slitter Head Coil Slitting Machine is an advanced metal processing system equipped with two independent slitting heads that allow simultaneous cutting of metal coils into multiple narrow strips, significantly boosting productivity and flexibility in high-volume production environments.

How Does a Double Slitter Head Machine Improve Productivity?

By featuring two slitting heads, the machine can process two sections of a coil at once or produce different strip widths in a single run, reducing setup time, minimizing downtime, and doubling output efficiency compared to single-head slitting lines.

What Materials Can Be Processed by the Double Slitter Head Machine?

The Lotosslitting Double Slitter Head Coil Slitting Machine handles a wide range of coil materials, including cold-rolled steel, stainless steel, aluminum, copper, and brass, with varying thicknesses and widths for diverse industrial applications.

What Are the Key Advantages Over Single Slitter Head Machines?

Compared to single-head models, the double slitter head design offers higher throughput, greater operational flexibility, reduced changeover time, improved material utilization, and the ability to run multiple product specifications simultaneously.

Is the Double Slitter Head Machine Suitable for Custom Slitting Needs?

Yes, Lotosslitting offers customizable Double Slitter Head machines with adjustable slitting widths, automated controls, and integration options to meet specific production requirements, making it ideal for both standard and specialized applications.

How Does Lotosslitting Ensure Precision in Its Slitting Machines?

Lotosslitting integrates servo-driven tension control, laser-guided alignment, precision-ground rotary knives, and PLC automation systems to ensure consistent, high-accuracy slitting results with minimal edge burr and width variation.

What Industries Benefit Most from This Slitting Technology?

Industries such as automotive, electrical manufacturing, construction, HVAC, and metal service centers benefit greatly from the speed, accuracy, and versatility of the Double Slitter Head Coil Slitting Machine for producing strips, laminations, and structural components.

Does Lotosslitting Provide Support and Maintenance Services?

Yes, Lotosslitting offers comprehensive after-sales support, including installation guidance, operator training, preventive maintenance programs, and technical troubleshooting to ensure long-term reliability and peak performance of your slitting machine.