the Role of a Cut to Length Line

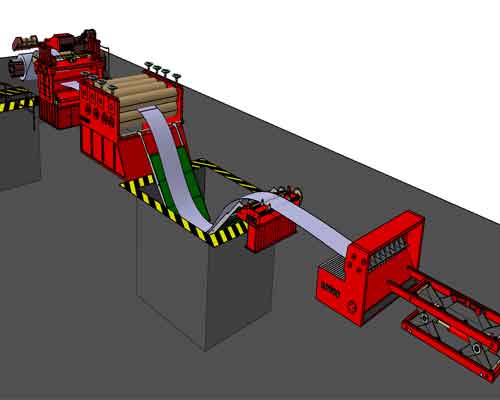

A cut to length (CTL) line is essential in metal processing, converting coils into flat sheets with precise dimensions. Before choosing a CTL line, it is important to understand its role in your production process and how it can improve efficiency, accuracy, and overall product quality.

How to choose a high quality cut to length line?

The first step in selecting a high-quality CTL line is evaluating your material requirements. Consider coil width, thickness, weight, and type of material to ensure the machine can handle your production demands. This assessment guarantees that the line you choose can deliver consistent results under your specific workload.

Evaluating Cutting Precision and Speed

Precision and speed are crucial factors in cut to length operations. A high-quality CTL line should offer accurate length cutting with minimal tolerances, even at high speeds. Investing in a line with advanced servo-driven controls and modern automation ensures efficient, precise output.

Considering Leveling and Straightening Performance

An excellent CTL line must provide reliable leveling and straightening of the material before cutting. This ensures the final sheets are flat and defect free, improving the quality of your finished products and reducing waste in downstream processes.

Checking Automation

Modern CTL lines feature user-friendly automation and control systems that streamline operations. Look for equipment with intuitive interfaces, programmable settings, and real-time monitoring to maximize productivity and reduce operator error.

Evaluating After Sales Service

A high-quality CTL line is more than just a machine; it is a long-term investment. Choose a manufacturer like Lotosslitting that provides comprehensive after-sales service, including installation, operator training, maintenance, and quick spare parts delivery to ensure smooth operations.

FAQ:

1- What factors should I consider when choosing a Cut to Length (CTL) line?

Key factors include material specifications (thickness, width, and type), cutting precision, production speed, leveling performance, automation features, and after-sales support from the manufacturer.

2- How can I ensure the CTL line handles my specific material requirements?

Check the machine’s technical specifications against your coil dimensions and material grades. A reputable supplier like Lotosslitting will offer custom solutions tailored to your production needs.

3- Why is leveling and straightening important in a CTL line?

Proper leveling and straightening ensure the final sheets are flat, defect-free, and consistent in quality, which is critical for downstream manufacturing processes.

4-What role does automation play in selecting a CTL line?

Modern automation improves efficiency, reduces operator error, and allows for real-time monitoring and adjustments, ensuring high productivity and consistent output.

5-Why should I choose Lotosslitting for my CTL line?

Lotosslitting combines advanced engineering, high-quality manufacturing, and comprehensive after sales service, making it the trusted partner for businesses seeking reliable CTL lines.