Double Slitter heads Slitting Line

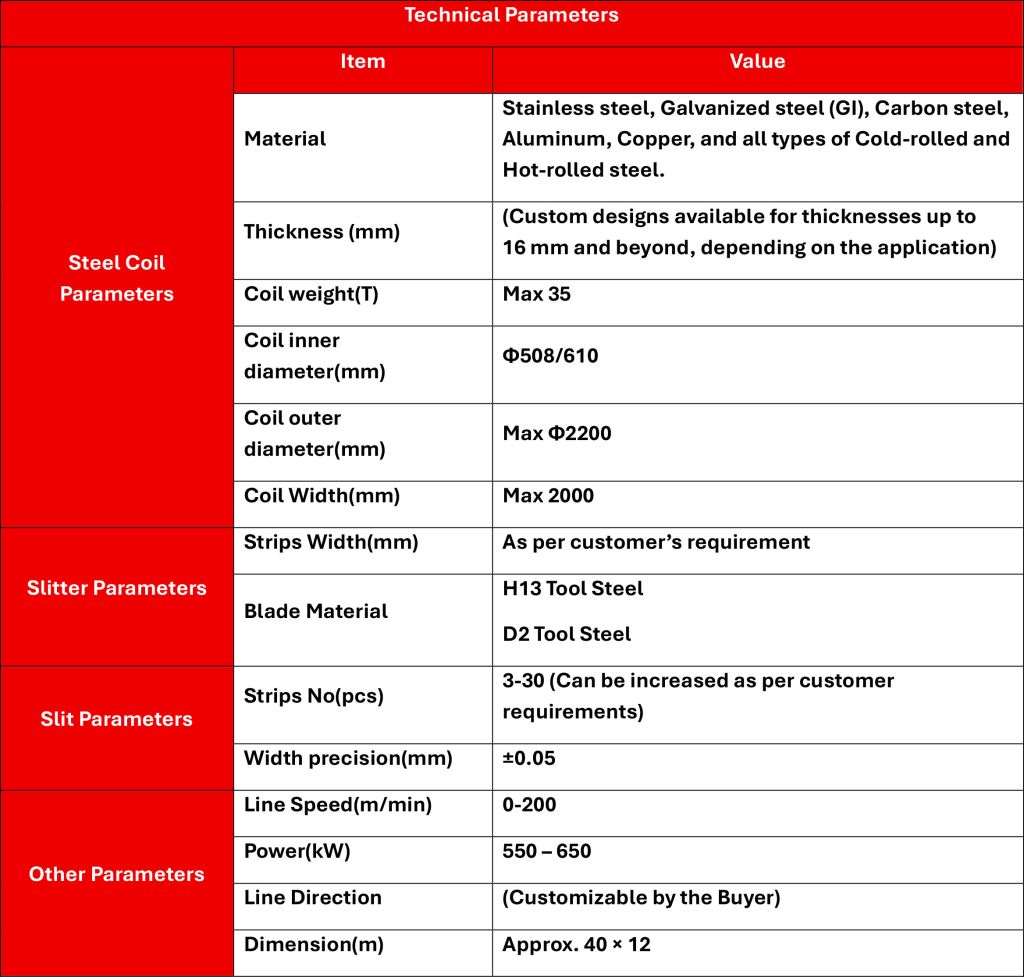

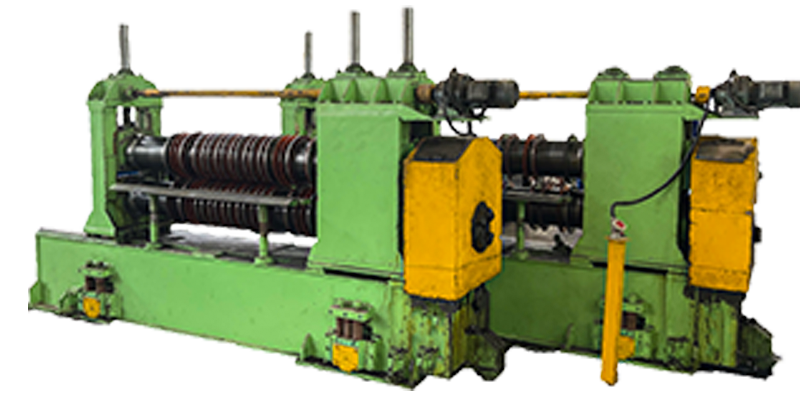

The LOTOS Double Slitter Heads Slitting Line is designed to significantly reduce downtime and improve operational efficiency in high volume coil processing. Traditional slitting lines with a single slitter head require the entire line to stop during knife setup, which impacts productivity. Our Twin Head Slitting Line eliminates this issue by integrating two independent slitter heads on a movable base frame. While one head is in operation, the other can be prepared offline, enabling faster job changeovers without interrupting production. Each slitter head can be identical or optimized for different material thicknesses, for example, a heavy duty head for thick-gauge coils and a lighter head for thin gauge materials, offering exceptional flexibility and precision. The Twin Head Slitting Line minimizes downtime and boosts overall productivity by allowing offline knife setup during live operation. Its dual-head flexibility enables seamless processing of various material thicknesses, making it ideal for high capacity steel service centers and coil processing facilities.

FAQ :

What is a Double Slitter Head Coil Slitting Machine?

A Double Slitter Head Coil Slitting Machine is an advanced metal processing system equipped with two independent slitting heads that allow simultaneous cutting of metal coils into multiple narrow strips, significantly boosting productivity and flexibility in high-volume production environments.

How Does a Double Slitter Head Machine Improve Productivity?

By featuring two slitting heads, the machine can process two sections of a coil at once or produce different strip widths in a single run, reducing setup time, minimizing downtime, and doubling output efficiency compared to single-head slitting lines.

What Materials Can Be Processed by the Double Slitter Head Machine?

The Lotosslitting Double Slitter Head Coil Slitting Machine handles a wide range of coil materials, including cold-rolled steel, stainless steel, aluminum, copper, and brass, with varying thicknesses and widths for diverse industrial applications.

What Are the Key Advantages Over Single Slitter Head Machines?

Compared to single-head models, the double slitter head design offers higher throughput, greater operational flexibility, reduced changeover time, improved material utilization, and the ability to run multiple product specifications simultaneously.

Is the Double Slitter Head Machine Suitable for Custom Slitting Needs?

Yes, Lotosslitting offers customizable Double Slitter Head machines with adjustable slitting widths, automated controls, and integration options to meet specific production requirements, making it ideal for both standard and specialized applications.

How Does Lotosslitting Ensure Precision in Its Slitting Machines?

Lotosslitting integrates servo-driven tension control, laser-guided alignment, precision-ground rotary knives, and PLC automation systems to ensure consistent, high-accuracy slitting results with minimal edge burr and width variation.

What Industries Benefit Most from This Slitting Technology?

Industries such as automotive, electrical manufacturing, construction, HVAC, and metal service centers benefit greatly from the speed, accuracy, and versatility of the Double Slitter Head Coil Slitting Machine for producing strips, laminations, and structural components.

Does Lotosslitting Provide Support and Maintenance Services?

Yes, Lotosslitting offers comprehensive after-sales support, including installation guidance, operator training, preventive maintenance programs, and technical troubleshooting to ensure long-term reliability and peak performance of your slitting machine.