What is Blade Setup in Slitting Lines?

At LOTOS, understanding the mechanics of blade layout is the foundation of achieving precision in every coil.

Proper industrial blade setup and alignment is critical for achieving precision, efficiency, and long-lasting performance in metal slitting lines. Whether you are slitting steel, aluminum, or other metals, correct blade positioning directly impacts product quality, machine longevity, and overall production efficiency.

In every high performance metal slitting line, accuracy begins with precise blade arrangement and alignment. At Wuxi LOTOS Roll Forming Co., Ltd., we believe that precision engineering starts long before cutting, with the correct setup geometry and calibration. Even the most advanced shear knives or arbors will fail to deliver quality if the setup geometry is incorrect. Improper blade spacing, misaligned arbors, or inconsistent spacer thickness can cause burrs, edge waves, camber, and strip width variations, all of which compromise downstream processes.

For manufacturers processing steel, aluminum, or copper coils, the correct blade arrangement ensures:

- Accurate slit widths within microns of tolerance

- Uniform edge quality

- Reduced mechanical vibration and bearing wear

- Extended blade and anvil life

Industrial Blade Installation Guide

Blade alignment ensures that each blade cuts accurately and consistently. Misaligned blades can lead to uneven cuts, burr formation, edge deformation, and increased wear on the machinery. Proper alignment minimizes downtime, enhances product quality, and reduces operational costs.

The Role of Knife Arbors and Spacer Rings

2.1. Knife Arbors

A slitter arbor is a high strength, precision ground shaft designed to hold multiple slitting knives, spacers, and rubber rings in a defined arrangement.

- The upper arbor carries the male knives, while the lower arbor carries the female or anvil knives.

- Both must remain perfectly parallel and concentric under operational load.

- Runout tolerance should not exceed 0.02–0.04 mm to maintain uniform slit widths.

2.2. Spacer Rings (Filler Rings)

Spacer rings, also called fillers or shims, are precision machined discs used to control the gap between adjacent blades.

- Each spacer defines the slit width and ensures equal strip separation.

- Typical spacer materials: hardened tool steel (HRC 60–64) or chrome-plated alloy steel for corrosion resistance.

- Spacer thickness must be verified with micrometers or laser gauges to ±0.01 mm accuracy.

Inaccurate spacer thickness leads directly to uneven coil widths and edge burr inconsistency.

Calculating Blade and Spacer Spacing

For accurate cutting, the total assembly height on both axes must be equal:

Explanation:

This ensures that the cutting line is straight and uniform. Each axis (top and bottom) must have the same total thickness, considering both knives and spacers.

Spacer Calculation

The total spacer width between left and right knife stacks is:

Blade Gap and Clearance Optimization

The blade clearance, the lateral distance between the cutting edges of the top and bottom knives, is crucial to achieving burr-free edges.

- Too large a clearance → rough, torn edges.

- Too tight → excessive side pressure, high wear, and burr formation.

Proper blade clearance also depends on the hardness of both knives and the tensile strength of the processed coil. LOTOS engineers recommend verifying clearances with optical gauges before production.

Parallel Alignment and Runout Reduction Techniques

Misalignment between arbors introduces side thrust and uneven loading. Proper alignment involves several key procedures:

5.1. Arbor Parallelism

- Measure parallelism using dial indicators mounted on precision frames.

- Adjust bearings until deviation ≤ 0.03 mm along the entire face length.

5.2. Blade Axial Runout

Runout results from non concentric knives or dirt between spacers.

- Always clean arbors and components before setup.

- Measure total indicated runout (TIR) with feeler gauges; regrind or replace defective components.

5.3. Thermal Stability

Temperature fluctuations can expand steel arbors. Maintain ambient operating temperature between 20–25°C and allow arbors to stabilize before calibration.

Controlling Vibration and Dynamic Balancing

At high line speeds (>150 m/min), even minor imbalance in the knife stack causes vibration, leading to poor cut quality and bearing wear.

6.1. Static and Dynamic Balancing

- Perform static balance by equalizing the knife stack weight along the arbor.

- For dynamic balance, use a vibration analyzer to detect imbalance frequencies.

6.2. Bearing Condition and Lubrication

- Worn bearings cause arbor runout and vibration; inspect after 1,000 operating hours.

- Use high-viscosity synthetic lubricants with extreme-pressure (EP) additives to reduce friction.

6.3. Rubber Rings and Separator Discs

Rubber rings (used to separate narrow strips) must be replaced regularly, as hardening leads to slippage or telescoping of slit coils.

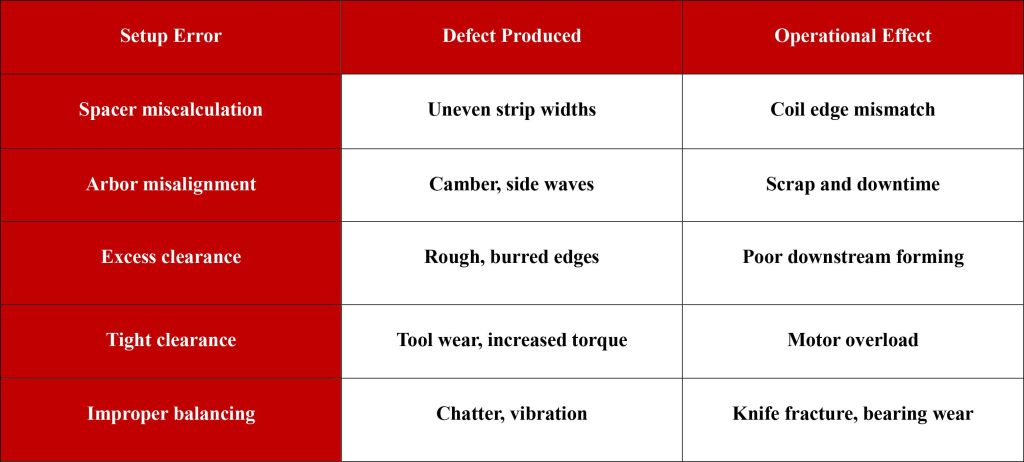

Impact of Incorrect Setup on Product Quality

Each issue can be traced back to improper setup geometry, reinforcing the necessity of precision in every component’s alignment.

Quality Control and Calibration Procedures

To maintain consistent cutting performance, LOTOS recommends the following QC routine:

- Pre Operation Check:

- Clean all blades, spacers, and arbors.

- Confirm arbor runout ≤ 0.04 mm.

- Dimensional Verification:

- Use calibrated micrometers and digital thickness gauges for spacer sets.

- Trial Slitting:

- Perform a sample slit and inspect both edges under magnification (≥20×).

- Post-Run Inspection:

- Measure burr height, camber, and width variation.

- Record results in a maintenance log for predictive trend analysis.

Consistency and documentation ensure long-term process stability and traceability.

- Advanced Methods: Digital Setup and Automated Alignment

Modern Wuxi LOTOS Roll Forming Machine Co., Ltd. slitting systems use blade alignment and digital arbor calibration. These systems use laser sensors and digital twin models to automatically:

- Measure actual versus theoretical spacer stack height.

- Adjust arbor parallelism in real-time.

- Detect microvibrations and compensate dynamically.

Such innovations reduce setup time by up to 40% and improve edge uniformity across high-speed production runs.

- Precision Setup Defines Edge Quality

Accurate blade arrangement is not a one-time task it’s an ongoing discipline. Every coil, spacer, and arbor assembly must be handled with the same precision as the blades themselves.

At Wuxi LOTOS Roll Forming Machine Co., Ltd., we understand that excellence in coil slitting comes from precision setup and control. Through controlled setup geometry, rigorous calibration, and continuous technological advancement, we deliver:

- High level accuracy in coil width and edge quality

- Optimized blade performance with minimal wear

- Reduced scrap rates and higher productivity

By integrating advanced alignment and monitoring solutions, LOTOS sets new global standards for metal slitting efficiency and precision.

FAQ :

1-What tools are used for blade setup and alignment?

Common tools include precision calipers, feeler gauges, dial indicators, and specialized blade alignment fixtures. Some modern slitting lines use digital measurement systems for faster and more accurate alignment.

2-Can incorrect blade setup damage the equipment?

Yes. Improperly set or misaligned blades can increase stress on the slitting shafts and bearings, leading to premature wear, machine downtime, and higher maintenance costs.

3-How can I optimize blade life in slitting lines?

To extend blade life, use high-quality blades suitable for the material being cut, maintain proper lubrication, perform precise alignment, and avoid excessive cutting speeds or feed rates.