INTRODUCTION

Advanced grinding and superfinishing of slitter blades play a crucial role in modern metal coil processing industries such as steel production, automotive manufacturing, metal packaging, and home appliances. In every slitting line, metal sheets are cut with high precision using extremely sharp circular blades, and the performance of these blades directly determines edge quality, burr levels, dimensional accuracy, machine vibration, and overall tool life. Because of this, the grinding and sharpening of slitter blades must be carried out with strict scientific principles, accurate grinding parameters, and controlled heat and force management.

Grinding is significantly more complex than conventional machining processes like turning or milling because thousands of abrasive grains interact with the blade surface simultaneously. Their combined cutting mechanics, plastic deformation, friction, and heat generation influence the final surface quality. Therefore, the evaluation of a ground slitter blade must consider two key factors: surface topography the micro-level grooves and ridges formed by abrasive grains and surface integrity, which includes hardness, residual stresses, microcracks, burn marks, and metallurgical changes.

For high-performance slitting operations, both factors are essential to ensure sharp geometry, long blade life, and damage-free cutting edges. At Wuxi LOTOS, we specialize in delivering advanced slitting lines, cut to length lines, and professional slitter blade grinding solutions across China.

This article provides a complete technical overview of the scientific principles behind grinding and superfinishing slitter blades, including wheel selection, grinding forces, heat control, vibration analysis, and best industrial practices.

Scientific Principles of Grinding Slitter Knives

In grinding, each abrasive grain acts like a very small cutting tool. Depending on shape, angle, size, and protrusion from the wheel surface, abrasive grains exhibit three main behaviors: Cutting, Plowing, and Sliding.

Understanding these behaviors is crucial for grinding slitting blades because the ratio between them determines final sharpness, heat generation, surface roughness, and the probability of burning.

2.1. Cutting (True Chip Formation)

In the Cutting state, the grain enters the material with a sharp angle and produces a real chip. This is the most desirable condition. Its outcomes:

- Lower energy

• Minimal heat generation

• Smoother surface

• Reduced burr

• Lower risk of metallurgical damage

Cutting is most effective when grains are sharp, dressing is performed correctly, and the depth of cut and speeds are properly selected.

2.2. Plowing (Deformation Without Chip Formation)

In Plowing, the grain cannot penetrate the material and instead pushes it sideways.

Results:

• Much higher energy

• High heat

• Higher roughness

• Lateral ridge formation on the surface

• Burr formation on the blade edge

Plowing indicates declining wheel performance, grain dulling, and insufficient dressing.

2.3. Sliding (Pure Friction)

In Sliding, the grain barely penetrates and mainly slides over the surface, generating friction.

This condition is also undesirable because:

• It produces significant heat

• It damages the surface

• It accelerates wheel dulling

Sliding increases when cooling is poor or the wheel is too hard.

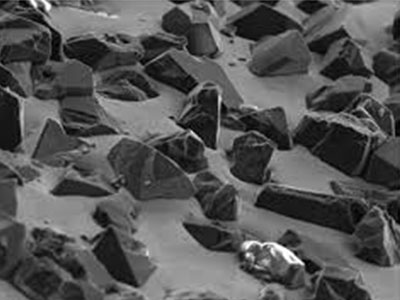

2.4. The Role of Grain Shape and Relative Speeds

Grain shape (sharp, rounded, polyhedral) and the relative speeds of wheel and workpiece determine which behavior dominates. Sharp, angular grains promote Cutting, while rounded grains tend to cause Sliding and Plowing. Higher relative speed increases Cutting, but if excessive and cooling is insufficient, heat rises.

- Selecting the Proper Grinding Wheel for Slitting Blade Sharpening

Four main parameters determine wheel selection: abrasive type, bond, grade, and structure.

Correct selection of these four factors has a decisive impact on blade quality.

CBN wheels, recommended by Lotos, provide the best balance of durability and precision for slitting blades.

3.1. Abrasive (Grain Material)

Three main families:

- Alumina (): for conventional steels

• Silicon Carbide (): harder, suitable for non-ferrous materials

• Diamond: for carbide

• CBN (Cubic Boron Nitride): the best choice for tool steels and slitting blades

What is CBN?

CBN is an ultra hard compound of boron and nitrogen in a cubic structure. This material:

- Has hardness nearly equal to diamond

• But unlike diamond, it does not react with iron

• Has excellent thermal and chemical resistance

• Maintains sharpness over long periods

Thus, CBN is the best option for HSS, D2, and other tool steels used in slitter knives.

3.2. Bond

The bond determines how grains are held together. Common types:

- Vitrified

• Resin

• Metal

• Electroplated

A harder bond increases wheel durability but may reduce self-sharpening.

For slitting blades, CBN wheels with vitrified or electroplated bonds are commonly used.

3.3. Grade (Wheel Hardness)

Grade indicates the wheel’s resistance to grain pull-out.

Soft Grade → grains detach faster → sharper surface → suitable for precision operations and reducing heat

Hard Grade → longer wheel life but less Cutting

For blades, soft to medium grades provide the best balance.

3.4. Structure (Porosity Level)

An open structure means more empty space between grains.

Advantages:

• Better coolant penetration

• Better chip evacuation

• Reduced heat

An open structure is ideal for slitting blades.

Dressing and Truing: Their Critical Role in Wheel Performance

4.1. Truing

Truing is the operation that corrects wheel geometry. If the wheel rotates eccentrically, has waviness, or improper shape, Truing restores it to the standard form (usually a perfect circle).

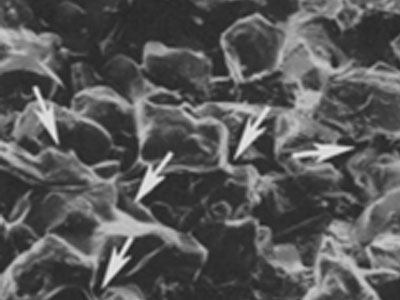

4.2. Dressing

Dressing sharpens the wheel surface. During dressing:

- Dull grains are removed

• New grains with proper protrusion are exposed

• Spacing between grains opens

• The wheel becomes ready for effective cutting

4.3. Grain Height After Dressing

When dressing is performed correctly:

- Grain tips typically protrude about half the actual grain size

• Grains with greater protrusion are the first active cutting points

• Low protrusion → increased plowing

• Excessive protrusion → grain breakage or pull-out

For slitting blades, precise dressing and protrusion control are critically important.

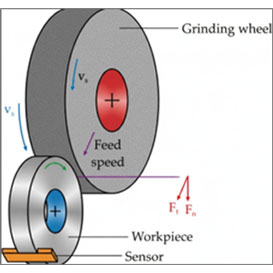

- Forces, Energy, and Grinding Mechanisms

5.1. Definition of Specific Energy

Specific energy is the amount of energy required to remove a unit volume of material:

Lower u means:

• A more efficient process

• Less heat generation

• More true cutting and less plowing/sliding

5.2. Components of Grinding Energy

Total energy consists of three parts:

- Cutting → low, desirable energy

• Plowing → high energy

• Sliding → very high and undesirable energy

5.3. Mechanical Interpretation of Specific Energy

Specific energy can also be expressed using the mechanical forces acting in grinding.

During grinding, two primary forces are generated:

- Tangential force ()

Acts along the wheel surface velocity direction.

This is the force that performs mechanical work and therefore determines the power: - Normal force ()

Acts perpendicular to the wheel surface.

It controls contact pressure, plowing, and wheel wear, but does not contribute to power, since it is orthogonal to the wheel velocity.

Only the tangential force appears in the specific-energy formulation.

If

- : tangential grinding force

- : wheel surface speed

- : true depth of cut

- : grinding width (the width of the actual material-removal zone in contact with the wheel)

- : workpiece feed speed

then:

where the material removal rate is:

Thus, specific energy represents the mechanical work (tangential force × wheel velocity) needed to remove a unit volume of material (depth × width × feed-rate volume flow).

5.4. Theoretical Chip Formation Energy

For steels, the theoretical chip-formation energy is approximately:

In real grinding, due to plowing and sliding, the actual specific energy becomes several times larger than this theoretical value.

5.5. The Advantage of CBN in Specific Energy

Because CBN abrasives maintain sharp cutting edges, their specific energy remains low and stable:

This low and consistent specific energy level is a key advantage of CBN in slitting-blade sharpening and other high-precision grinding operations.

- Heat in Grinding and Its Risks

Heat is the most important factor causing damage during blade grinding.

High temperature causes:

• Burn

• Tempering

• Re-austenitization

6.1. Thermal Models

At the wheel–blade contact zone, a “moving heat source” is generated. Part of the heat goes into the chip, part into the wheel, and a significant portion into the blade surface.

6.2. Why Does the Blade Edge Burn More Easily?

The blade edge:

- Has very little mass

• Has limited heat conduction

• Acts as a peak

Low-mass regions cannot dissipate heat and heat up quickly, leading to bevel-edge burning.

- The Role of Coolant and Contact Phenomena

Since previous sections explained that heat is a critical factor in slitting blade grinding, it is natural that coolant plays a major role in controlling the process. In addition to temperature control, proper coolant supply modifies grain–metal contact behavior and reduces undesired effects such as excessive Plowing or Adhesion.

7.1. Coolant Role and Adhesion

An effective coolant system must:

- Operate with high flow rate

• Provide sufficient pressure to reach the contact zone

• Strike directly at the cutting point

• Penetrate between wheel grains

This is even more important for CBN wheels because the removal rate and contact speed are high, increasing the risk of instantaneous temperature spikes.

7.2. Adhesion

If the metal gets too hot or the coolant does not sufficiently penetrate the surface, metal particles adhere to abrasive grains.

This causes:

• Wheel dulling

• Increased heat

• Increased energy consumption

• Higher roughness

Regular dressing and adequate cooling are the main ways to reduce Adhesion.

- Surface Quality: Morphology, Ra, Edge Radius, and Microcracks

After controlling heat and contact behavior, the most important indicator of success in grinding is the resulting surface quality. The surface quality of a slitting blade affects not only cut precision but also tool life and stable performance in high-speed lines.

Our customers using Wuxi Lotos slitting machines report consistently high surface quality and edge precision.

8.1. What Is Surface Morphology?

Morphology refers to the formation of grooves, lines, and ridges created by grain paths. It directly depends on:

- Wheel topography

• The chip thickness generated at each point

8.2. Key Surface Quality Criteria

- Ra: surface must be very smooth (around 0.2 μm or less).

• Edge Radius: smaller radius yields a sharper edge and better cutting performance.

• Microcracks: these microdefects must not exist.

• No burn: any discoloration or softening indicates thermal damage.

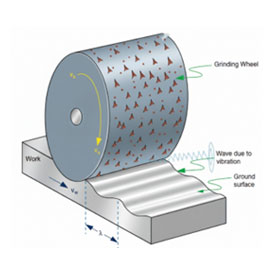

- Vibration (Chatter) and Its Role in Blade Grinding

Vibration must be examined because even slight dynamic instability between the wheel and blade directly affects roughness and edge accuracy. Chatter is a self-excited, sustained vibration that may occur intentionally or unintentionally.

Chatter results:

• Increased roughness

• Higher energy and heat

• Serrated edges

• Reduced blade life

Causes of chatter:

• Poor wheel balance

• Fixture looseness

• Insufficient system stiffness

• Improper machine parameters

Solutions:

Proper balancing, increased rigidity, parameter adjustment, and accurate dressing.

9.1. Forced Vibration and Waviness

Forced vibrations of the grinding wheel can generate periodic waviness on the workpiece surface, which directly affects the surface roughness and edge quality of the blade. The characteristic wavelength of these surface waves is given by:

where:

- is the feed velocity of the workpiece,

- is the vibration frequency of the grinding wheel.

Effects of wavelength on surface quality:

- Small : Closely spaced waves result in higher surface roughness and serrated edges.

- Large : Widely spaced waves, which may be visually apparent but have lower roughness.

Understanding allows the operator to optimize feed velocity and machine conditions to minimize waviness, improve edge quality, and maintain dimensional tolerances. This quantitative analysis links mechanical vibrations to measurable surface characteristics, complementing the qualitative discussion of chatter.

- Roughing and Finishing in Sharpening

After reviewing all influencing factors in grinding, the practical structure of the sharpening process must be summarized. Blade sharpening is usually carried out in two main stages:

10.1. Roughing

- Removing initial stock

• Using coarse grains

• Larger depth of cut

• Rougher surface

10.2. Finishing

- Minimal material removal

• Using fine grains

• Producing a very smooth surface

• Achieving a sharp, burr-free edge

Recommended cycle for slitting blades:

Roughing → Dressing → Finishing → Spark-out