Heavy Gauge Slitting Line by LotosSlitting is engineered for processing thick steel coils with maximum precision and strength, delivering efficient, accurate, and durable performance for heavy-duty metal industries.

Heavy gauge Slitting Line

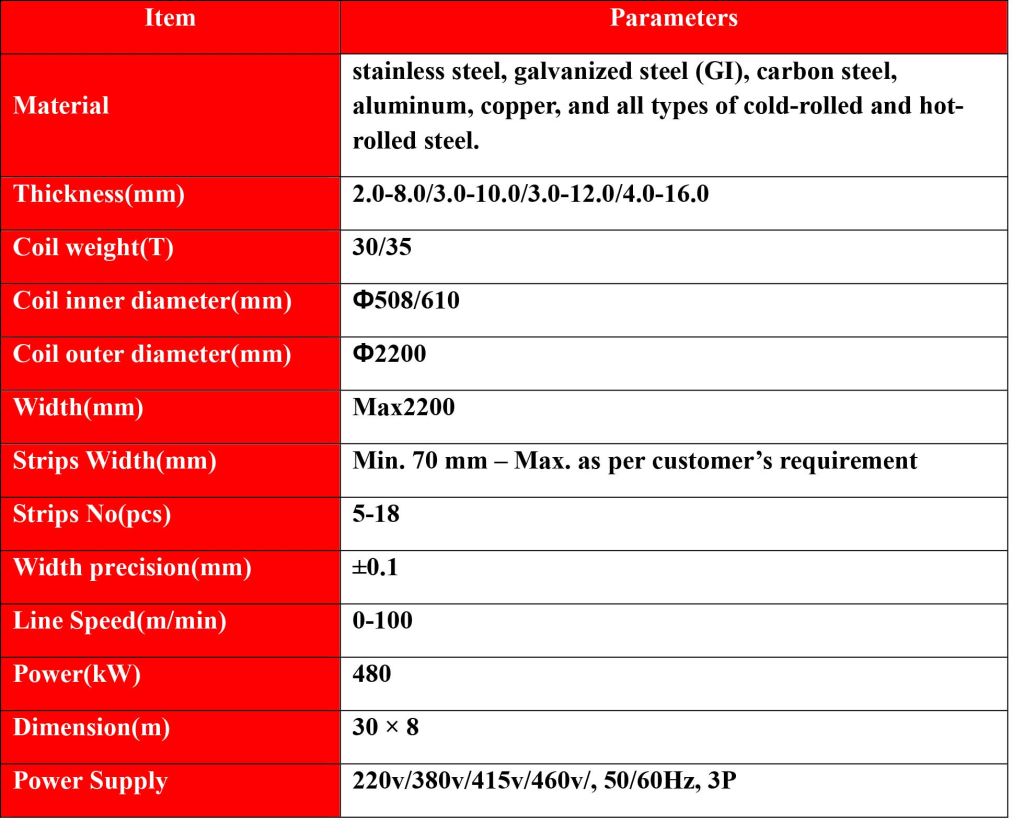

The LOTOS Heavy Gauge Slitting Line is designed to accurately slit wide metal coils over 10 mm in thickness and up to 35 tons, ensuring stable and precise performance under heavy duty conditions. Equipped with a robust hydraulic decoiler, motorized blade positioning, a feedback controlled tension system, and a torque balanced heavy duty recoiler, this line delivers burr free, consistent-width strips even under demanding industrial loads. The mechanical structure is engineered to minimize vibration and maintain alignment across the full width of the strip during high-speed operation. All motion and process parameters are managed by an intelligent automation platform, providing synchronized line control, recipe management, and real time diagnostics. The LOTOS Heavy Gauge Slitting Line guarantees precision, durability, and minimal maintenance, making it ideal for heavy-duty industrial environments.

Steel Slitting Line

The process begins with the uncoiling of the metal coil by the uncoiler. Next, the sheet passes through the leveling unit to eliminate internal stresses and achieve a smooth, uniform surface. After leveling, the sheet enters the slitting unit, where precision blades cut the sheet into narrow strips with a cutting tolerance of ±0.05 mm. This step is performed with high accuracy to avoid any cutting errors or warping.

The cut strips are then drawn through guide systems and fed into the recoiler, where they are rolled back into narrower coils. Finally, the output coils are prepared for packaging and shipping. This fully automatic line is controlled by a PLC system and industrial user interface, enabling easy adjustments, precise monitoring, and rapid execution of the slitting operations.