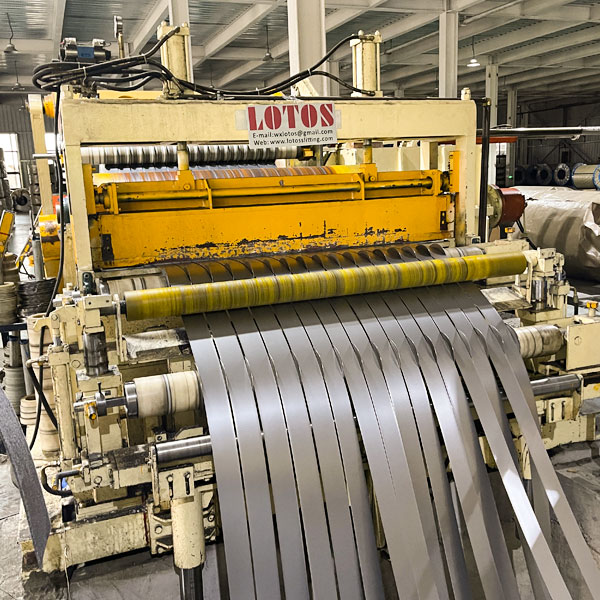

High Speed Slitting Machine

To maintain peak performance, the (0.5-3.5)×1650mm High Speed Slitting Line requires regular maintenance and careful handling. Routine checks of the machine’s components, such as blades, bearings, and hydraulic systems, are essential to prevent wear and tear and extend the equipment’s lifespan. Lubrication of moving parts, timely replacement of worn out components, and calibration of control systems help ensure smooth and reliable operation. Operators must also be trained to handle the machine correctly, following safety protocols and operational guidelines. A proactive maintenance approach not only reduces downtime but also maximizes the machine’s efficiency and productivity, resulting in a better return on investment.

(0.5-3.5)×1650mm High Speed Slitting machine

Main technical parameters:

| Steel coil parameters | Material | HR, CR, GI, ZM, PPGI |

| Tensile strength | Max 540MPA | |

| Steel thickness | 0.5-3.0mm | |

| Steel width | 600-1650mm | |

| Steel coil I.D | Φ480-Φ508 mm | |

| Steel coil O.D | Φ1800mm(Max) | |

| Steel coil weight | 25T(Max) | |

| Slitter parameters | knife pivot diameter | Ф220 mm |

| Knife pivot material | 42CrMo | |

| Blades specification | Φ180mmXφ240mmX5mm | |

| Blade material | SKD-11 | |

| Slit parameter | Max slit quantity | 50 strips @ T=0.5mm

30pcs(0.3-1mm) |

| 20 strips @ T=1.0mm | ||

| 6 strips @ T=3.0mm | ||

| Width precision | ≦0.2mm(T=1.2-3.0mm)

≦0.3mm(T=3.0-6.5mm)

|

|

| Other parameters | Power | 380V/50Hz/3Ph |

| Line speed | 0-120m/min | |

| Capacity | 420KW | |

| Line direction | From right to left

(Face to machine) |

|

| Machine color | Red & Gray |