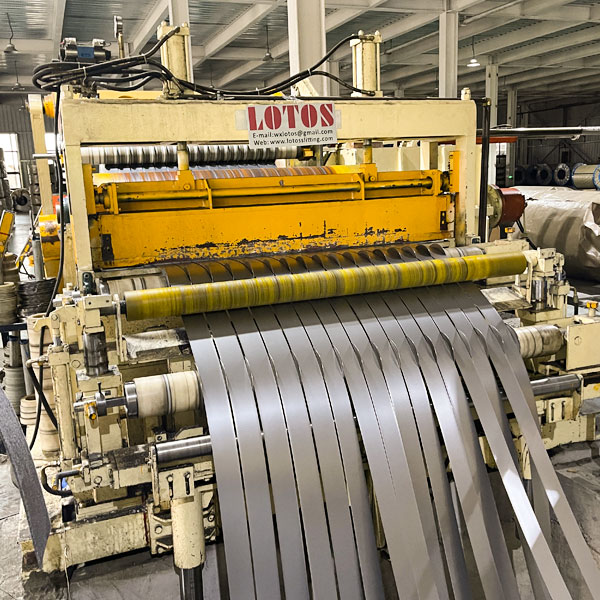

High Efficiency Metal Processing

The 3*1650mm slitting line epitomizes High Efficiency Metal Processing, combining speed with precision

to deliver superior results. Its robust design and advanced features contribute to High Quality

Coil Slitting, ensuring that each strip meets stringent quality standards. The machine’s ability

to maintain tight tolerances, even at high speeds, makes it invaluable for industries requiring precision

cut metal strips.Additionally, its energy efficient operation and minimal material waste further enhance

its appeal as a cost effective solution for modern metal processing facilities aiming to optimize their

production processes while maintaining the highest quality standards.