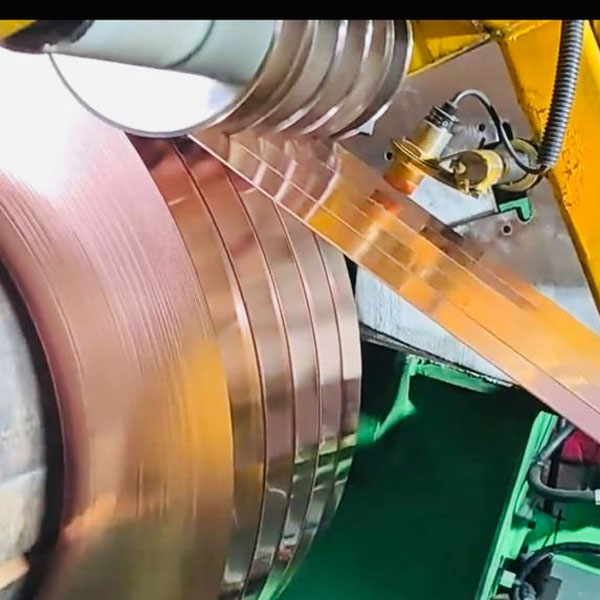

Coil slitting line

Coil slitting lines are essential tools in the sheet metal industry, enabling the production of narrower widths from a master coil of steel. These lines offer increased efficiency, precision, flexibility, and automation, making them indispensable for high-volume production environments. By understanding the components, types of slitting heads, and key considerations when choosing Coil slitting lines, you can optimize your sheet metal manufacturing process and achieve superior results.

Main technical parameters :

|

Steel coil parameters |

Material |

CRS and GI |

|

Tensile strength |

δb≤500Mpa, δS≤260Mpa |

|

|

Steel thickness |

1-4.0mm |

|

|

Steel width |

300-1600mm |

|

|

Steel coil I.D |

φ480-508 mm, could beφ610mm |

|

|

Steel coil O.D |

Φ630-Φ2200mm |

|

|

Steel coil weight |

15T |

|

|

Slitter parameters |

knife pivot diameter |

Ф240 mm |

|

Knife pivot material |

42CrMo |

|

|

Blades specification |

Φ240mmXφ360mmX5mm |

|

|

Blade material |

SKD11 |

|

|

Slit parameter |

Max slit quantity |

10pcs@4mm 20pcs(1-2mm) 30pcs(0.3-1mm)

|

|

Width precision |

≤±0.05mm(T=1.0mm) |

|

|

Other parameters |

Power |

380V/50Hz/3Ph |

|

Line speed |

0-100m/min,

3-4

|

|

|

Capacity |

About 380 Kw |

|

|

Whole line Dimension |

23mX10m 25m(L)X8m(W) |

|

|

Operator needed |

1 mechanical engineer,2 common workers |

|

|

Line direction |

From left to right(Face to machine) |

|

|

Machine color |

Red & Gray |

Working Flow:

From right to left: Entry coil car → Decoiler →Press and pinch device → Hydraulic cutter → Looper 1→Side guide device→ Slitter → Scrap winder → Looper 2→Tension stand → Recoielr → Exit coil car