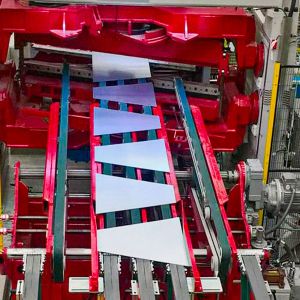

Cut to Length Machine

Cut to length machines have revolutionized the manufacturing industry by offering a highly efficient and precise

method for cutting metal coils into desired lengths.These machines have become an integral part of various

sectors, including automotive, construction, and appliance manufacturing. In this comprehensive guide,

we will explore the cut-to-length process, advantages of using this Heavy Gauge Cut To Length Line,

different types available, key components, selection criteria, operation and maintenance, common

challenges, popular brands and models, cost considerations, and where to buy. By the end of this guide,

you will have a comprehensive understanding of Heavy Gauge Cut-To-Length Line and how they can

benefit your business.

Technical Parameter:

|

No |

Name |

Unit |

Parameter |

|

1 |

Tensile strength |

|

δb≤650Mpa |

|

2 |

Control model |

|

PLC frequency control |

|

3 |

Applied to |

|

Carbon steel ,GI ,PPGI and others |

|

4 |

Thickness |

mm |

2-8 |

|

5 |

Width |

mm |

800-1500 |

|

6 |

ID |

mm |

Φ500-800 |

|

7 |

OD |

mm |

≤2000 |

|

8 |

Coil weight |

Ton |

≤20 |

|

9 |

Diameter of leveling roller |

mm |

150 |

|

10 |

Distance of leveling rollers |

mm |

165 |

|

11 |

Number of leveling rollers |

|

17 |

|

12 |

Material of leveling roller |

|

GCr15, hardness:HRC55-60 |

|

13 |

Material of cutter blade |

|

6CrW2Si |

|

14 |

Speed (without cutting stop) |

m/min |

≤40 |

|

15 |

Cutting speed |

pcs |

12-15 per minute for 2m length |

|

16 |

Direction of feed material |

|

from right to left |

|

17 |

Length tolerance |

|

L=2m≤±1 mm |

|

18 |

Diagonal tolerance |

|

L=2m≤±2 mm |

|

19 |

Power |

|

380V/3PH/50HZ (customized) |

|

20 |

Capacity |

KW |

Around 140 |

|

21 |

Area of the whole production line |

|

about 24m(L)X8m(W) |

|

22 |

People of operation |

workers |

1 technician and 2 general |