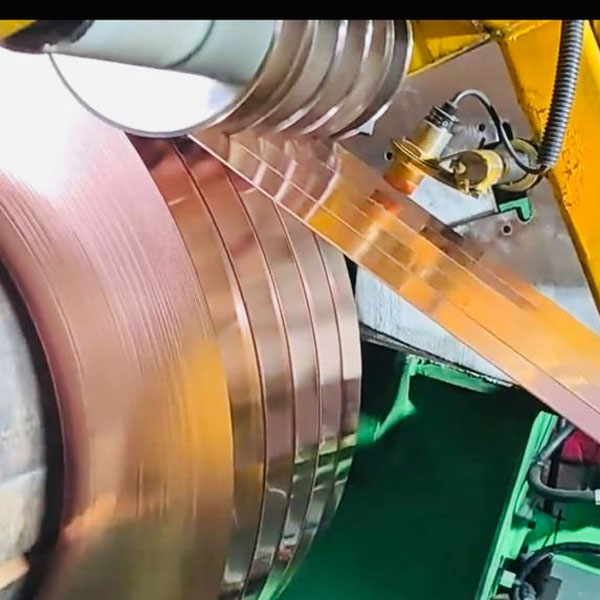

Slitting lines for heavy gauge

(2-10)×1500MM HEAVY GAUGE SLITTING LINE: The complete set of equipment for the Metal slitting line manufactured by LOTOS SLITTING has the characteristics of advanced technology, reliable equipment, perfect technology, mature manufacturing, and convenient maintenance. Ensure product dimensional accuracy, surface quality, production efficiency, and other requirements.

details are as follows:

The uncoiling, slitting, straightening and transverse shearing unit mainly adopts feeding → uncoiling → feeding pinch and rough leveling → reference side guide → slitting → looper → tension → coiling → crossing bridge → straightening → length cutting → horizontal Cutting → conveying → stacking and other processes.

1. technical specifications of the production line:

a. Raw material specifications

Material type stainless steel plate hot rolled plate cold rolled plate, galvanized plate pickled plate high strength steel plate

Coil Thickness Minimum 1.5mm ~ Maximum 10mm

(Small Tool Holder 1.5-6)

Coil Width Minimum 70mm ~ Maximum 1500mm

Coil weight up to 30,000 kg

Coil inner diameter φ610mm

Coil outer diameter Min φ800 mm~Max φ2,000mm

Tensile strength up to 800MPa

Yield strength max 650MPa

b. Finished product specification

Finished product width minimum 40mm ~ maximum 1500mm

Number of processing strips ≤4 (10MM), 6mm 9 strips 8mm 6 strips

The minimum trimming amount is 5mm on one side, normal production (within 3mm)

Finished coil weight up to 25,000 kg

Finished product inner diameter φ508mm (plus diameter sleeve)

Finished outer diameter φ2000mmMax,

Finished length min 500mm ~ max 4000mm

Stacking height 600mm

Maximum stacking weight 6,000 kg

Heavy Duty Slitting Line

c. Cutting accuracy

Length accuracy (single strip) ±1mm

Length accuracy (multiple) ±2.5mm

Diagonal accuracy (1 meter X 1 meter) ≤ 1.5mm (subject to no adverse effects of raw materials)

Burrs ≤ 3% of plate thickness, sharp knives, moderate knife gap.

Width accuracy ≤0.20mm within 1.5-5 10mm 5-10mm

Camber accuracy ≤2mm/1m (subject to no adverse effects of raw materials)

Edge burrs 3% of plate thickness (moderate knife clearance, sharp knife)

Coiling staggered layer ≤±3mm

Coiling tower shape ≤±4.0mm (the first 5 layers are not counted)

d. Other main parameters

Unit running direction Facing the unit from right to left.

Shearing speed Working speed 0~60m/min

Threading speed about 10-15m/min

Line height FL. + 1000 mm

Straightening roller system Quadruple 11-roller straightening

Electrical system AC 380 V 50 Hz

Air pressure system 5 ~ 7 Kg/c㎡ air consumption

Hydraulic system High pressure 100 Kg/c㎡ (commonly used)