Stainless Steel Overview for Engineers and Manufacturers

Stainless steel is one of the most strategic and essential metal families in today’s industrial world. Due to its unique combination of corrosion resistance, mechanical strength, formability, high temperature performance, and long service life, stainless steel plays a critical role across various industries. Since the introduction of the first stainless steel in the 1910s, these alloys have evolved significantly. Today, hundreds of stainless steel grades are defined under EN, ASTM, JIS, and ISO standards, each tailored for specific environments and applications. Wuxi LOTOS Roll Forming Machine Co., Ltd is recognized as one of the leading manufacturers of stainless steel slitting lines and cut to length lines in China, offering enhanced automation for high precision stainless steel coil processing.

Why Stainless Steel Matters

- Passive Layer Formation: A thin, adhesive chromium oxide layer protects against corrosion.

- Exceptional Durability: Many stainless steel structures and equipment operate for decades without replacement.

- Hygiene and Cleanliness: Ideal for food processing, pharmaceutical manufacturing, and medical applications.

- Wide Range of Mechanical Properties: From highly ductile grades to high-strength stainless steels.

- Nearly 100% Recyclable: Among the most sustainable engineering materials worldwide.

This guide provides a complete and practical overview of stainless steel families, mechanical and physical properties, grade selection principles for industrial applications, equivalency across global standards, and behavior in slitting processes, equipping engineers and manufacturers with actionable insights.

Stainless Steel Classification

Stainless steels are categorized into five main families based on metallurgical structure and mechanical behavior. Understanding this classification is crucial for proper grade selection, component design, and slitting line operations. Understanding these material families is essential for the design of LOTOS high accuracy stainless steel slitting lines, engineered to deliver burr-free cuts and perfect tension control across all grades.

- Ferritic Stainless Steels

- Structure: Ferritic (BCC)

- Magnetic: Yes

- Nickel Content: Very low or none

- Cost: Economical and stable

Figure 1: Body-Centered Cubic (BCC) Structure

Corrosion Resistance: Basic to moderate

- Formability: Good, especially in deep drawing; lower surface stretch than austenitic

- Weldability: Moderate, brittle at high thicknesses

Applications:

- Home appliances (washing machines, refrigerators)

- Automotive exhausts

- Light tanks and equipment

- Interior architectural components

- Moderate temperature applications

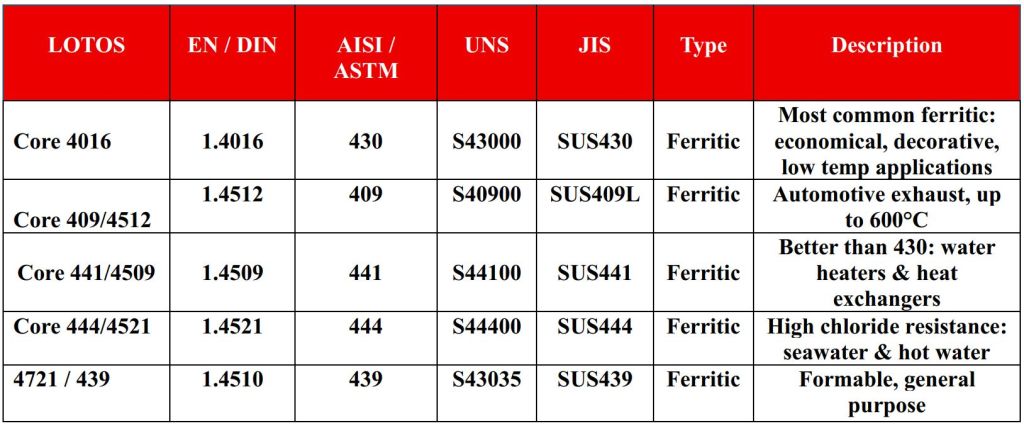

Common Grades:

- EN 1.4016 (AISI 430)

- EN 1.4509 / 1.4510 (Stabilized Ferritic)

- EN 1.4521 (High Cr Ferritic)

- Martensitic Stainless Steels

- Structure: Martensitic (BCT)

- Magnetic: Yes

- Key Feature: High strength and hardness

- Corrosion Resistance: Low to moderate

Figure 2: Body-Centered Tetragonal (BCT) Structure

Heat Treatment: High hardenability

Applications:

- Blades and knives

- Shafts, axles, and pumps

- Tools and wear-resistant parts

- Turbine components

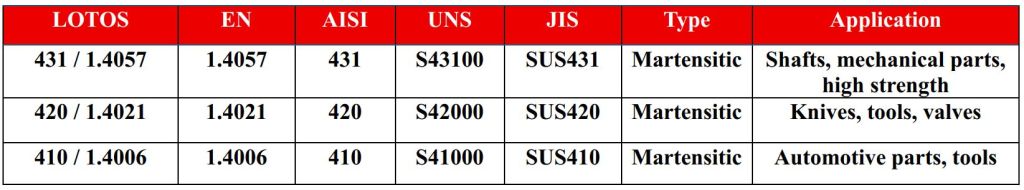

Common Grades:

- EN 1.4021 (AISI 420)

- EN 1.4006 (AISI 410)

- EN 1.4542 (17-4PH, Precipitation-Hardened)

- Austenitic Stainless Steels

- Structure: Austenitic (FCC)

- Magnetic: No (unless work-hardened or welded)

- Nickel Content: Present

Figure 3: Face-Centered Cubic (FCC) Structure

Corrosion Resistance: Medium to very high

- Formability: Excellent

- Weldability: Excellent

- Work Hardening: Significant (critical for slitting)

Applications:

- Food and pharmaceutical industries

- Chemical processing equipment

- Cryogenic and LNG equipment

- Architectural structures

- Coastal applications

Common Grades:

- EN 1.4301 / 1.4307 (304 / 304L)

- EN 1.4404 / 1.4432 (316L / Mo-alloyed)

- 904L (High corrosion resistance)

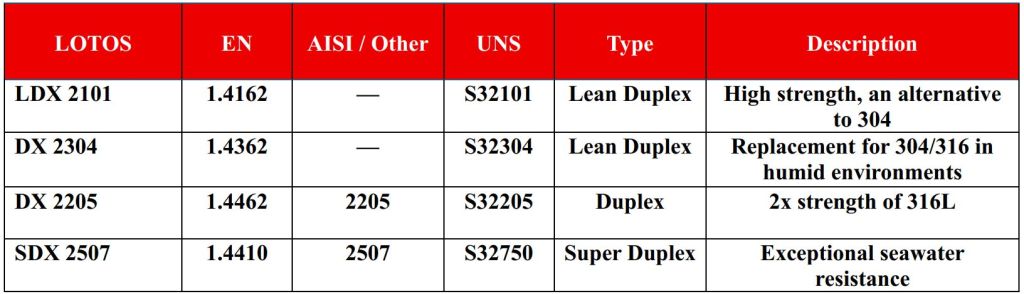

- Duplex Stainless Steels

- Structure: Approximately 50% ferritic + 50% austenitic

- Strength: ~2x austenitic

- Corrosion Resistance: High

- Stress Corrosion Cracking (SCC) Resistance: Excellent

- Temperature Range: Typically -40°C to +250°C

Applications:

- Chemical tanks

- Bridges and heavy structures

- Pulp and paper industry

- Oil & gas

- Seawater applications

Common Grades:

- EN 1.4162

- EN 1.4362 (2304)

- EN 1.4462 (2205)

- EN 1.4410 (2507 Super Duplex)

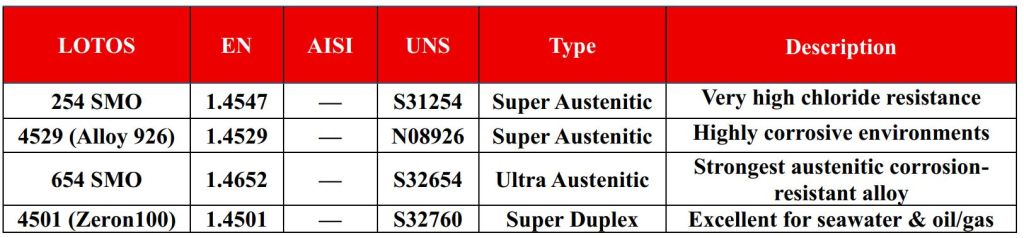

- Super Austenitic and Super Duplex Stainless Steels

- Structure: Highly alloyed austenitic or duplex

- Features:

- Exceptional resistance to localized corrosion

- Excellent performance in acidic environments

- SCC and SSC resistance

- Critical, high-performance applications

Applications:

- Offshore oil & gas

- Desalination plants

- Extreme-duty heat exchangers

- Chlorine, acid, and halogen industries

- Cooling towers

Key Grades:

- EN 1.4547

- Alloy 28 (EN 1.4563)

- 4529 (Alloy 926)

- UNS S32654

Mechanical and Physical Properties of Stainless Steel

Stainless steels combine corrosion resistance with valuable mechanical and physical properties that make them suitable for challenging industrial environments, including precision processes such as stainless steel slitting.

Mechanical Properties

- Yield Strength (Rp0.2):

- Austenitic: 200–300 MPa

- Ferritic: 280–330 MPa

- Duplex: 450–550 MPa (~2x 304/316)

- Super Duplex: >600 MPa

- Ultimate Tensile Strength (Rm):

- Austenitic: 520–750 MPa

- Ferritic: 450–550 MPa

- Duplex: 650–800 MPa

- Toughness:

- Austenitic steels perform exceptionally at low temperatures (ideal for cryogenic applications).

- Ferritic and duplex steels can be brittle at very low temperatures.

- Hardness (HBW Average):

- Ferritic: 160–200

- Austenitic: 150–190 (with significant work hardening)

- Duplex: 220–270

- Martensitic: 200–500 (depending on heat treatment)

Slitting Insight:

- Austenitic steels harden during cutting → higher blade load and increased burr.

- Duplex steels → higher hardness → increased tool wear.

- Ferritic steels → easier and more stable slitting performance.

- Martensitic steels → require carbide blades and reinforced tooling.

LOTOS control adjusts speed, tension, and gap automatically based on grade, enhancing accuracy while reducing operator dependency.

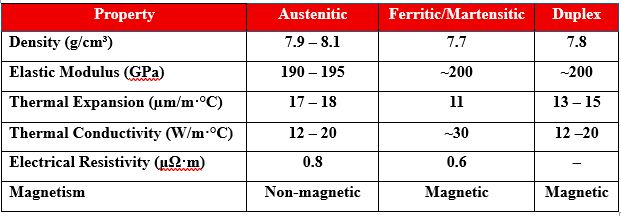

Physical Properties

LOTOS stainless steel slitting lines solve these challenges with real time blade alignment, precision tension control, and low scratch handling systems.

Slitting Implications:

- Austenitic steels → high springback → precise tension control required

- Duplex steels → harder → slower cutting speeds

- Ferritic steels → stable, simple cutting

- Martensitic steels → require carbide blades

Material Selection Principles

Correct stainless steel grade selection is critical for industrial applications. Improper selection can lead to premature corrosion, high maintenance costs, reduced equipment life, or structural failure.

Key Selection Factors

- Corrosive Environment: Type, chloride content, pH, temperature, gases, chemical exposure

- Mechanical Requirements: Yield strength, tensile strength, toughness, creep resistance, hardness, wear

- Manufacturing Process: Forming, bending, welding, cutting/slitting, surface finishing

- Operating Temperature: Austenitic → excellent at low temperatures; Duplex → limited to ~250–325°C

- Cost (Life Cycle Cost – LCC): Material cost, service life, maintenance, repair, replacement, and recyclability

Grade Recommendations by Application

- Food Equipment → 304 / 316

- Chemical Industry → 316L / 904L / 254 SMO

- Oil & Gas → Duplex / Super Duplex

- Architecture → 304 / 316 / Ferritic 4510

- Bridges & Structures → Duplex 2205

- Tanks → 316 / Duplex

- Automotive Exhaust → Ferritic 409 / 4512

Slitting-Specific Guidance

- 304 / 304L → best overall, work hardens

- 316 / 316L → slightly softer than 304

- Ferritic → easiest to slit, low burr

- Duplex → hard, requires precise clearance + carbide blades

- Martensitic → very hard, carbide blades mandatory

Ferritic Stainless Steels:

Austenitic Stainless Steels:

Martensitic Stainless Steels

Duplex Stainless Steels:

Super Austenitic & Super Duplex

Challenges and Best Practices

Slitting is a critical process, ensuring coil widths meet precise customer requirements across industries: food, pharma, oil & gas, automotive, home appliances, and architectural panels. LOTOS machinery combines premium blades with automatic force monitoring to ensure consistent performance at high speeds.

Key Slitting Challenges for Stainless Steel

- Higher strength → increased cutting force

- Springback in austenitic & work-hardened grades

- High hardness in duplex & martensitic

- Low-temp toughness concerns

- Scratch-sensitive surfaces

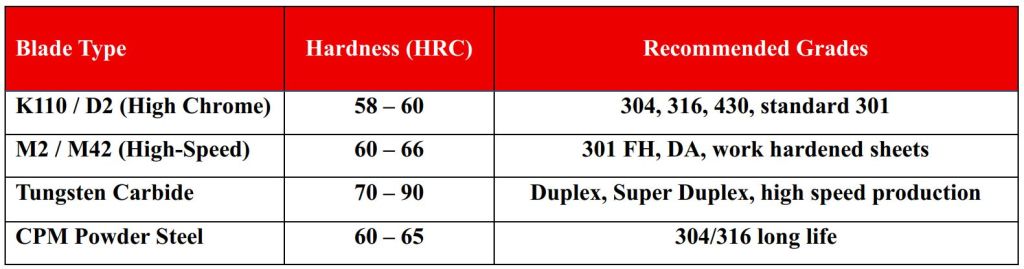

Blade Selection for Stainless Steel Slitting

LOTOS control systems recommend optimal cuts, speeds, and gaps based on coil thickness and mechanical behavior, significantly reducing setup time.

Engineering Recommendations:

- Duplex → Carbide cutter

- 304/316 → D2 or CPM

- Work-hardened 301 → M2/M42

Slitting Parameters

- Clearance (Blade Gap): Depends on thickness (0.01–0.12 mm range)

- Slitting Speed:

- Austenitic: 80–150 m/min

- Ferritic: 120–180 m/min

- Duplex: 40–100 m/min

- Tension Control: Critical to prevent edge waviness, burr, coil set

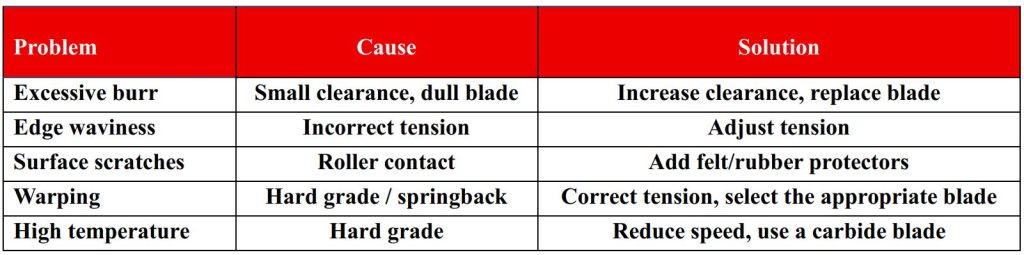

Common Slitting Issues & Solutions

LOTOS diagnostic software identifies burrs, edge waves, and tension errors in real time before they affect coil quality.

Maintenance and Equipment Longevity

Preventive Maintenance (PM): Daily, weekly, monthly, and quarterly checks can reduce repair costs by 30–50%.

Blade Maintenance: Monitor burr, edge wear, heat, and re-sharpen according to grade.

Slitter Head: Check shims, shaft hardness, and dynamic balance.

Rollers & Tension System: Ensure proper coating, load cell functionality, vibration control.

Decoiler & Recoiler: Maintain tension control, surface protection, and mandrel pressure.

Scratch Prevention: Use felt protectors, cleaning brushes, and PE film to prevent surface damage.

Operator Checklist: Daily checks for clearance, blade condition, roller health, and tension.

Sustainability, Environmental Impact, and Recyclability

- Near 100% recyclability without quality loss

- 82–90% of global production from scrap → reduces raw material, energy, and CO₂

- Modern furnaces & scrap usage → 20–33% CO₂ reduction

- Passive layer → non-toxic, safe for water, food, and closed environments

- Nickel content → non-allergenic, suitable for medical tools & implants

- Economic advantages → long life reduces overall costs

Conclusion: Stainless steel is a green, durable, and cost-effective material for future industries.

Why Stainless Steel Matters for Slitting

- Structural Diversity & Grades: Austenitic, Ferritic, Martensitic, Duplex, Super Alloys

- Mechanical & Physical Properties: High strength, toughness, formability, wear resistance

- Grade Selection Principles: Corrosion environment, mechanical requirements, LCC

- Maintenance & Repair: Corrosion control, proper cleaning, and slitting line upkeep

- Sustainability: 85%+ recyclable, 20–30% lower CO₂, safe, long-lasting

Slitting Specific Insights

- Duplex & Martensitic → higher pressure and tool wear

- Austenitic → higher adhesion & burr → precise tension control needed

- Sensitive finishes (BA, No.4) → scratch-free rollers and surface protection required

Competitive Advantage & Marketing

- Demonstrating deep expertise in stainless steel behavior builds trust

- Professional slitting line design for sensitive sheets

- Increased customer confidence and sales, standing out from competitors

Final Takeaway

Complete knowledge of material, mechanical properties, surface sensitivity, and environment is essential for professional stainless steel slitting lines. Investing in stainless steel ensures durability, quality, sustainability, and cost effectiveness for advanced industries. With a strong presence in China and worldwide, WUXI LOTOS ROLL FORMING MACHINE CO., LTD delivers one of the most advanced stainless steel slitting and cut to length solutions, powered by precision engineering.