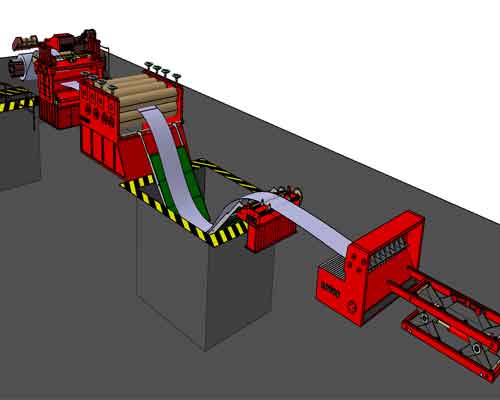

Slitting Line :

The LOTOS Slitting Line is an advanced system designed to uncoil wide metal coils, slit them into narrower strips with precise widths, and then rewind them into separate coils. These lines are suitable for a wide range of materials, including stainless steel, galvanized steel (GI), carbon steel, aluminum, copper, hot rolled steel, and cold rolled steel. The system is composed of key components such as the uncoiler, press and pinch, slitter, edge scrap winder, tension control unit, and recoiler—all operating fully automatically with high accuracy and efficiency. To ensure long-term reliability and stable performance, LOTOS slitting lines are equipped with electrical and control components from internationally recognized brands such as Siemens, Omron, and Schneider. Slitting speed can be customized based on the production needs, with standard models available in a range of 30 to 180 meters per minute. Lines with speeds exceeding 80 m/min are categorized as high-speed slitting lines. This flexibility in design allows the system to be optimized for various material types, production volumes, and specific technical requirements. Each LOTOS slitting line can be fully customized in terms of size, speed, blade configuration, and control systems to meet the precise demands of different industrial applications.

CUT-TO-LENGTH LINE:

Cut-to-length technology enables the precise cross-cutting of metal coils into flat sheets) with defined lengths and geometries. These sheets are then stacked and prepared for further processing or direct use. At LOTOS, our cut-to-length lines are designed for efficiency, accuracy, and adaptability across a wide range of metals and coil formats, including hot-rolled steel, cold-rolled steel, galvanized steel (GI, GL), pre-painted steel (PPGI/PPGL), stainless steel, carbon steel, aluminum, and copper. Depending on production needs, our systems can be equipped with either stationary shears (stop-and-go operation) or flying shears for continuous high-speed processing, combined with optimized stacking solutions for seamless material handling. Each line configuration is tailored to specific production goals, taking into account factors such as material type, sheet thickness, output dimensions, and desired throughput. All LOTOS lines are fitted with precision leveling systems to ensure flatness and surface integrity.

The best products of our company

Steel Slitting Lines are essential in the steel processing industry, designed to cut large steel coils into narrower strips. These strips are customized to meet the specific width requirements of customers, enabling further use in manufacturing processes. The precision and efficiency of slitting lines directly impact the quality of steel products, making them critical in producing high-quality steel components. In contrast, CTL lines are designed to uncoil steel, level it, and cut it into flat sheets of desired lengths. These lines ensure precision in sheet dimensions, essential for industries requiring flat steel components.

Lotos Slitting’s expertise in steel slitting machines and CTL lines makes it a trusted choice for businesses aiming to enhance production efficiency and product quality.

Metal Slitting Machines

Steel coil slitting is a metal cutting process where large rolls or a wide sheet steel coil are cut

using very sharp rotary blades.

Though called a STEEL COIL SLITTING LINE, such a processing line also use for equipped to slit ferrous metals, nonferrous

metals, and aluminum.

definitely, stainless steel slitting lines are

vital in the manufacturing industry as they provide efficient and precise cutting of stainless steel coils into narrower strips. These slitting lines offer flexibility in terms of material grades and thicknesses, allowing manufacturers to meet various customer requirements.

in brief, The advancements in steel slitting line technologies have further enhanced efficiency by providing advanced monitoring and control systems.

With these systems, manufacturers can

track and analyze the performance of the slitting process, ensuring optimal productivity. The use of steel coil slitting machines also improve the production process by offering improved

accuracy and consistent cuts. This minimizes material waste and optimizes the use of

stainless steel coils.

Additionally, stainless steel slitting lines streamline operations by automating

the cutting process, reducing the time and effort required to produce smaller stainless

steel strips. Overall, the utilization

of stainless steel slitting lines plays a

crucial role in enhancing efficiency and streamlining operations in the manufacturing industry.

slitting line use to produce smaller coils that are cut into narrower widths.

Steel coil slitting is a metal cutting process where large rolls or a wide sheet steel coil are cut using very sharp rotary blades.

How to use the slitting machine?

But how do you actually use the slitting machine? Let’s find out!

First things first, you need to ensure that your steel coil slitting line is set up correctly. This includes making sure that the machine is properly aligned and the blades are in good condition. Once everything is in order, it’s time to load the coil onto the machine. Gently place the coil onto the mandrel and secure it tightly. This will ensure that the coil stays in place during the slitting process.

Now that your coil is securely in place, it’s time to set up the slitting parameters. This includes adjusting the speed, tension, and width of the slit. Each metal material may require different settings, so it’s important to consult the manufacturer’s guidelines or seek expert advice if needed. Once you’ve dialed in the perfect settings, it’s time to start the slitting process.

Engage the slitting blades and watch in awe as they effortlessly slice through the metal coil. The precision and speed of a steel coil slitting line is truly a sight to behold. As the machine continues to cut through the coil, make sure to monitor the quality of the slit. If any issues arise, such as uneven cuts or jagged edges, it may be necessary to make adjustments to the slitting parameters.

Once the slitting process is complete, it’s time to unload the slit coils. Carefully remove each coil from the mandrel and inspect them for any defects or imperfections. If all looks good, stack the coils neatly and prepare them for further processing or shipment. It’s important to handle these slit coils with care, as they can be quite heavy and sharp.

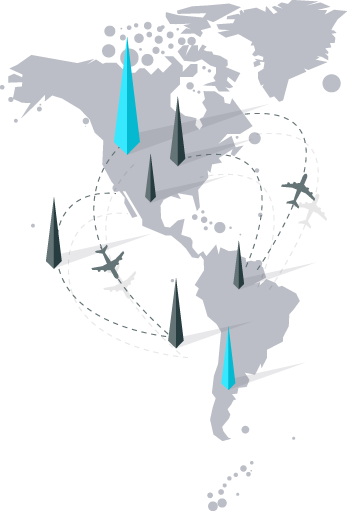

- United Arab Emirates

- China

- America

After extensive research, we chose the Trapezoidal Shear Cut To Length Line from Lotus Slitting. This machine can be easily adjusted to any required size, and the cut quality is outstanding. Their 10-year warranty is a clear sign of their confidence in their products. We are very satisfied with our choice.

For our aluminum cutting project, we purchased an Aluminium Slitting Line from Lotus Slitting. The machine works perfectly and exactly meets our needs. Most importantly, the 10-year warranty and strong after-sales service allow us to use it with confidence.