WHAT IS THE SLITTING VS. CUT-TO-LENGTH PROCESS?

Both of these machines have their own unique set of features and functionalities that make them stand out. So, let’s dive right in and explore the wonderful world of slitting lines and cut to length machines.

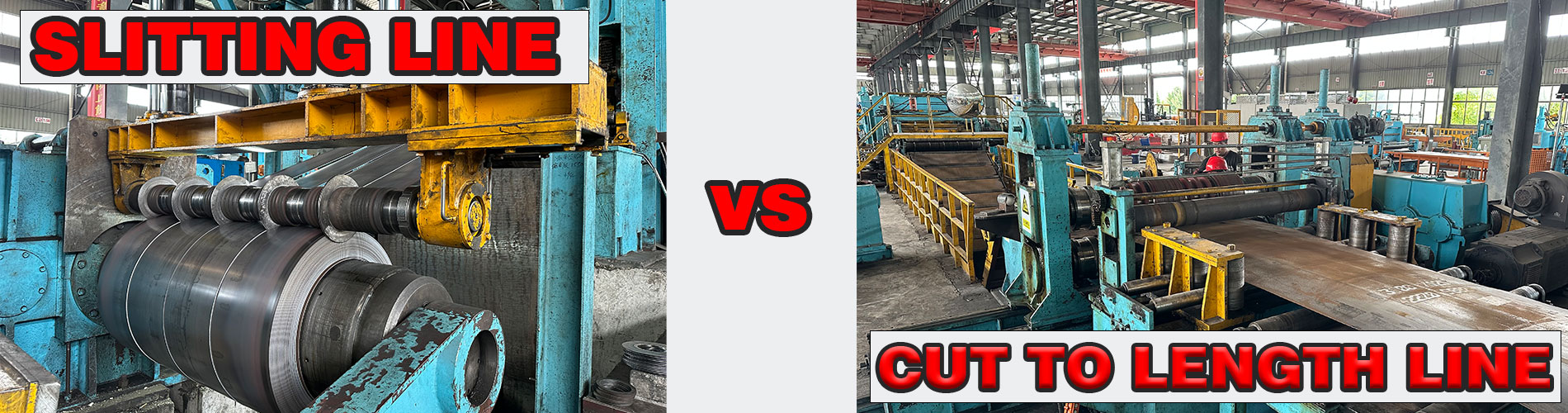

First things first, let’s talk about what a slitting line is. A slitting line is a machine that is used to cut wide coils of steel into narrower strips. It is perfect for industries that require different widths of steel strips for their production processes. The slitting line works by feeding the coil through a set of rotating circular blades that make precise cuts along the length of the coil. The strips are then wound onto separate recoilers, ready to be used for various applications. With a slitting line, you can easily obtain multiple narrower strips from a single wide coil, making it a highly efficient and cost-effective solution.

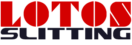

On the other hand, a cut to length machine, as the name suggests, is used to cut steel coils into specific lengths. This machine is ideal for industries that require standard-sized sheets or plates for their manufacturing processes. The cut to length machine works by feeding the coil through a straightening unit that removes any deformations in the material. Then, using a guillotine shear or rotary shear, the machine cuts the coil into precise lengths as per the required specifications. These cut pieces are then stacked or transferred onto a conveyor belt for further processing. With a cut to length machine, you can easily obtain accurately sized sheets or plates with minimal wastage.

Slitting & Cutting-To-Length Lines

Another difference lies in the output produced by each machine. A slitting line can produce multiple strips of varying widths from a single coil, whereas a cut to length machine produces sheets or plates of specific lengths. This variation in output allows manufacturers to cater to different customer requirements and enhances overall production flexibility.

Furthermore, the setup and configuration of each machine differ significantly. A slitting line requires additional components such as decoilers, looping pits, edge trimmers, and recoilers to efficiently process wide coils into narrow strips. On the other hand, a cut to length machine typically consists of a straightening unit, shear, and conveyor belt for processing coils into specific lengths.

In conclusion, both slitting lines and cut to length machines play crucial roles in steel processing. While a slitting line focuses on transforming wide coils into narrow strips, a cut to length machine specializes in cutting coils into specific lengths. Each machine offers unique benefits and caters to different industry requirements. So whether you’re in need of narrow strips or accurately sized sheets, there’s a machine out there waiting to meet your steel processing needs!