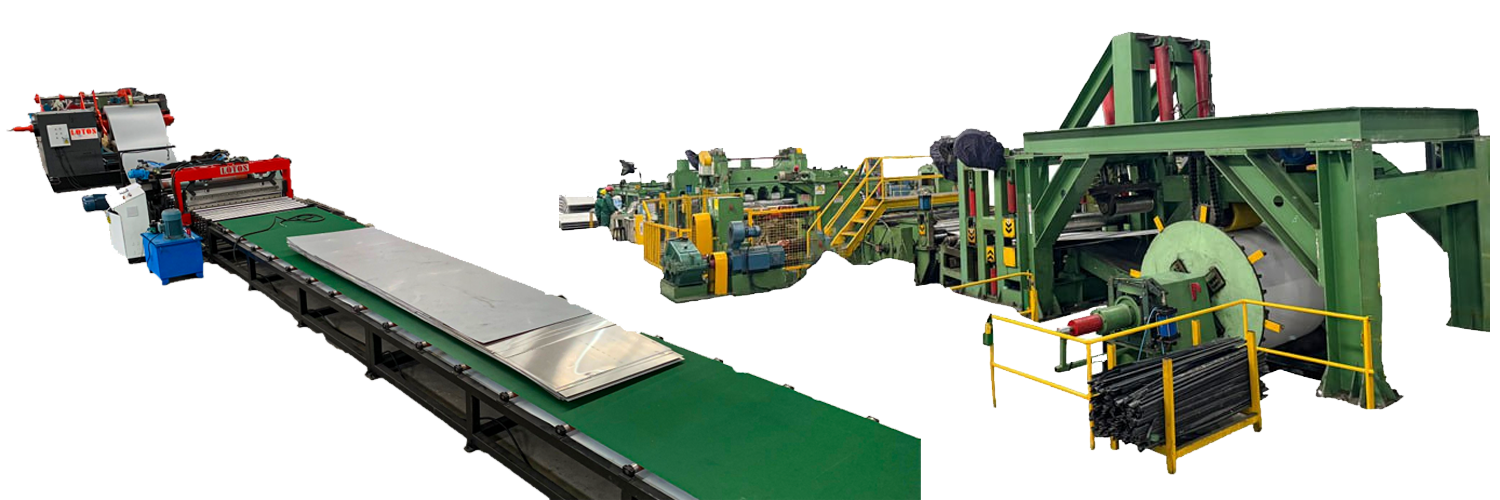

Cut-To-Length Lines

Cut-to-length lines are advanced machines designed for precision and efficiency in cutting materials to specified lengths. Equipped with state-of-the-art sensors and controls, these systems automate the entire process. Users can input the desired length, and the machine takes care of the rest, including measuring, cutting, and stacking the finished pieces. This high level of automation not only saves significant time but also reduces errors and inconsistencies, ensuring a high-quality output with minimal human intervention.

LOTOS SLITTING stands out for its expertise in designing and manufacturing high-performance slitting equipment. The company is committed to delivering comprehensive solutions, encompassing processing capacity, quality assurance, labor safety, operational efficiency, and system reliability. Their scope of responsibility extends to the entire lifecycle of the equipment, including supply, transportation, installation, foundation construction, operation guidance, and commissioning.

A key feature of LOTOS’s slitting lines is the integration of two main leveling machines. This configuration ensures optimal leveling of steel plates across a range of thicknesses, enhancing the precision and consistency of the final output. This advanced design reflects LOTOS’s focus on quality and versatility in handling diverse production requirements.

.