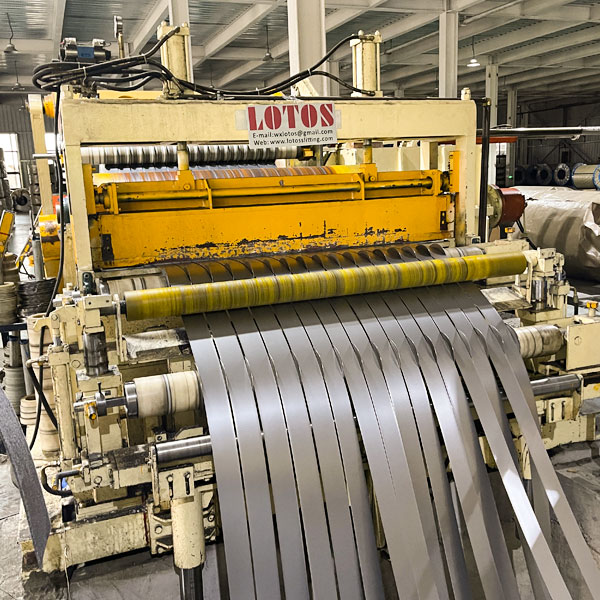

high-speed steel slitting machine

the slitting machine is a game-changer for any industry that deals with cutting materials into narrower strips. With its remarkable speed, versatility, and accuracy, this machine is sure to revolutionize your workflow. Say goodbye to manual cutting methods and embrace the efficiency and precision of the slitting machine. Invest in this incredible technology today and take your business to new heights!

Main technical parameters:

|

Steel coil parameters |

Material |

ST14-Carbon steel-Galvanezed steel |

|

Tensile strength |

δb≤550Mp δS≤260Mpa |

|

|

Steel thickness |

0.3-4.0mm |

|

|

Steel width |

300-1650mm |

|

|

Steel coil I.D |

Φ610 ⁓760mm |

|

|

Steel coil O.D |

Φ2000mm |

|

|

Steel coil weight |

25 TON |

|

|

Slitter parameters |

knife pivot diameter |

Ф240 mm |

|

Blades specification |

Φ240mmXφ360mmX15mm |

|

|

Blade material |

SKD11 |

|

|

Slit parameter |

Max slit quantity |

0.5 40 STRIPS,1.5 20 STRIPS, 4 mm 8 STRIPS |

|

Width precision |

≤±0.05mm |

|

|

Other parameters |

Power |

380V/50Hz/3Ph |

|

Line speed |

0-100m/min,

3-4

|

|

|

Capacity |

About 380 Kw |

|

|

Whole line Dimension |

32mX10m 25m(L)X8m(W) |

|

|

Operator needed |

1mechanicalengineer,2common workers |

|

|

Line direction |

From left to right(Face to machine) |

Working Flow

From right to left: Entry coil car → Decoiler →Press and pinch device → Hydraulic cutter → Looper 1→Side guide device→ Slitter → Scrap winder → Looper 2→Tension stand →Tension leveling → Electrostatic oil spraying system → Recoiler → Exit coil car