Automatic Strip Packing Machine

An Automatic strip packing machine is the crucial final step for protecting slit steel coils (strips) after precision slitting. This specialized equipment efficiently wraps individual slit coils or bundles them securely before applying protective layers like film, paper, or foam. By automating this process, manufacturers eliminate slow, inconsistent manual packing, dramatically increasing output while ensuring every strip coil is uniformly shielded from moisture, corrosion, and physical damage during transit and storage. This precision is vital for maintaining the quality of high value slit products delivered from your lotosslitting line.

Automatic Coil Packing Line Manufacturer

Selecting a reliable Automatic coil packing line manufacturer is a critical investment decision for any steel processor. Look for manufacturers with deep industry expertise, proven technology, and a strong track record in designing robust systems tailored to specific coil weights, sizes, and packaging requirements (weatherproof, anti-scratch, VCI). A top tier manufacturer doesn’t just supply machinery; they become a partner, offering comprehensive support from initial consultation and custom engineering through installation, training, and responsive after sales service to ensure your lotosslitting operation achieves maximum uptime and packing efficiency.

Steel Coil Handling and Packing Line

Integrating a complete Steel coil handling and packing line transforms logistics from the slitting line to shipping.This system seamlessly links processes: starting with automated coil pickup via lifting and tilting equipment, precise weighing, through surface cleaning, then into the core packing machinery for end face protection, inner/outer wrapping, banding, and labelling. This holistic automation minimizes manual lifting, reduces handling damage risks, optimizes floor space, and creates a continuous, high throughput flow that perfectly complements your lotosslitting output, ensuring coils are protected and ready for customers faster.

Automatic Steel Coil Packing Machine

At the heart of any automated system lies the Automatic steel coil packing machine. This sophisticated unit performs the core wrapping and protection tasks with precision and speed. Utilizing advanced servo controls, it accurately applies multiple layers of protective materials stretch film, craft paper, VCI paper, plastic sheets, cushioning – and secures them with steel or plastic strapping. Features like automatic coil centering, adjustable wrapping tension, and programmable recipes ensure consistent, high-quality packaging for every single coil, regardless of diameter or weight, directly enhancing the value proposition of your lotosslitting services.

Coil Packaging Line for Peak Performance

A well designed Coil packaging line is more than just machinery; it’s a synchronized production cell. Optimization involves selecting the right combination of handling equipment, packing machines, and material feeding systems to match your specific throughput, coil dimensions (ID/OD/weight), and required packaging standards. Modern lines offer flexibility for different packaging types (full cover, side-only, diamond wrap) and materials, controlled via intuitive HMIs. Integrating this line seamlessly with your lotosslitting operation eliminates bottlenecks, reduces labor dependency, and delivers a significant return on investment through consistent quality and speed.

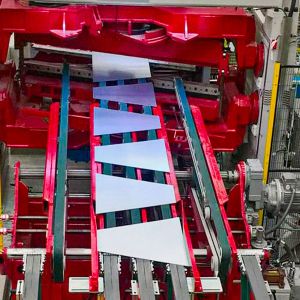

Steel Strip Wrapping & Stacking Production Line

1.2 Technical Parameters:

– Coil width: 30–200 mm

– Inner diameter: 508 mm

– Outer diameter: 800–1100 mm

– Max weight per coil: ≤1000 kg

– Max stacking height (incl. pallet): 1000 mm

1.3 Requirements:

– Compact layout, advanced technology, safe and reliable.

– Low energy consumption, easy maintenance, operated by 1–2 workers.

– Full quality control within design scope.

2. Equipment Composition:

1. Rotary Single Arm Loader (12T)

2. Powered Turnover Car with Roller Conveyor

3. Rotating Strapping Station (optional)

4. Fork-ready Powered Roller Conveyor

5. Automatic Handling & Stacking System

6. Palletizing Roller Conveyor

7. Output Roller Conveyor

8. Electrical Control System