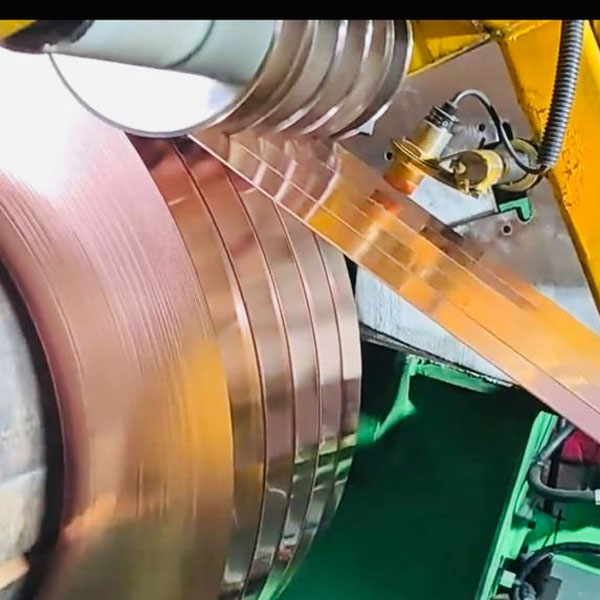

Slitting Lines For Brass

Introducing the BRASS SLITTING MACHINE by LOTOS. Designed to deliver exceptional precision, this machine sets the bar high for slitting metal strips of copper and brass. With a massive coil weight capacity of up to 1 ton and a width capability of 400mm, it effortlessly handles your slitting needs. Seamlessly slice through brass with ease, thanks to this cutting-edge slitting line. Upgrade your production process with the BRASS SLITTING MACHINE and experience unparalleled efficiency and quality.

Material Specifications:

- Material Type: Brass coils, typically consisting of various brass alloys such

as CZ108 (CW508L), CZ120 (CW608N), etc. - Material Thickness: Typically ranges from 0.1 mm to 2.0 mm, though this can vary

based on specific machine capabilities and customer requirements. - Coil Width: Usually handles coils with widths ranging from 100 mm to 1500 mm, but

again, this can vary based on machine design and application.

2. Slitting Parameters:

- Number of Slitting Blades: A typical slitting line may have multiple slitting heads equipped

with circular knives or rotary slitters depending on the required precision and production speed. - Minimum Strip Width: The narrowest strip width that can be reliably produced by the machine,

often as narrow as 10 mm or less. - Tolerance: Precision in maintaining strip width consistency across the coil length, usually specified

within ± 0.05 mm to ± 0.2 mm depending on the application.

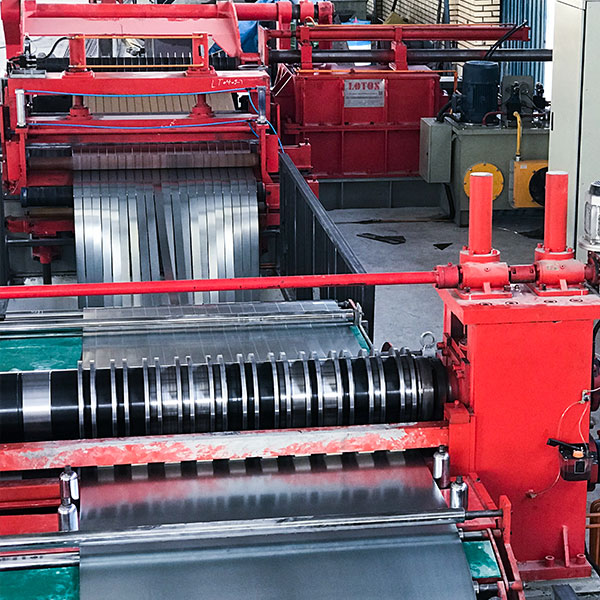

SLITTING LINES FOR COPPER & BRASS

3. Line Speed and Capacity:

- Line Speed: Operational speeds can range from 30 meters per minute (m/min) to over 150 m/min,

depending on the thickness of the material and the complexity of the slitting process. - Maximum Coil Weight: Typically handles coil weights ranging from 3 tons to 20 tons or more, depending

on the design and intended application of the slitting line. - Maximum Coil Outer Diameter (OD): The maximum diameter of the brass coil that can be

processed, often ranging from 1200 mm to 2000 mm.

4. Feeding and Uncoiling System:

- Coil Car: Heavy-duty equipment used for loading and unloading coils onto the slitting line.

- Decoiler: Hydraulic or motorized decoilers capable of handling coils with inner diameters

(ID) ranging from 508 mm (20 inches) to 760 mm (30 inches). - Loop Control: Tension control systems to maintain proper material tension and prevent coil

slippage or deformation during the slitting process.

5. Slitting and Recoiling System:

- Slitting Heads: Multiple slitting heads equipped with precision slitting knives or blades, capable

of achieving clean, burr-free cuts. - Separators: Systems to separate and guide the individual strips after slitting, ensuring proper

alignment and preventing tangling. - Recoiler: Hydraulic or motorized recoilers capable of rewinding the slit strips into coils of specified

dimensions with tight tolerances.

BRASS SHEET CUTTING MACHINE

6. Control and Automation:

- Control System: Advanced PLC (Programmable Logic Controller) and HMI

(Human-Machine Interface) for precise control of slitting parameters, automatic

adjustment, and real-time monitoring of production parameters. - Automatic Adjustment: Automatic setup and adjustment of slitting parameters such as

blade positioning, strip width, and tension control based on predefined settings. - Safety Features: Comprehensive safety features including emergency stop buttons, safety

interlocks, and protective guarding to ensure safe operation for operators and maintenance personnel.

7. Power and Utilities:

- Power Requirements: Electrical power supply specifications, typically ranging from 380V

to 480V AC, three-phase, 50 Hz or 60 Hz. - Compressed Air: Pneumatic systems for blade actuation and other auxiliary

functions, requiring clean and dry compressed air supply.