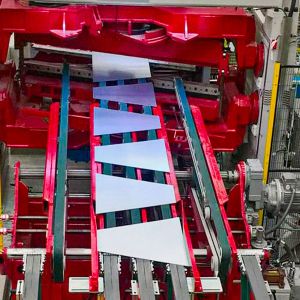

Ctl Machine

One of the standout features of the Light Gauge Cut-To-Length Lines is its unparalleled accuracy. With its precise measurements and automated cutting capabilities, you can trust that each cut will be flawless. No more worrying about uneven edges or wasted materials. This machine ensures that every piece is cut to the exact specifications, saving you time, money, and resources.

Our cut-to-length machine incorporates state-of-the-art technology to ensure precise measurements and automated cutting capabilities. No more second-guessing or wasting valuable resources on re-cuts. With our machine, you can trust that each cut will be exact, saving you time, money, and materials.

Not only do our Light Gauge Cut-To-Length Lines deliver exceptional accuracy, but it also boasts a user-friendly interface for seamless operation. Its intuitive controls make it easy for anyone to achieve professional results without extensive training.

High Speed Cut to Length Line

A thin gauge Cut to Length Line is designed for processing lightweight coils of thin materials (typically 0.2-2.0 mm). These lines operate at high speeds with precision leveling and cutting systems, ensuring minimal surface damage and tight length tolerances.

| Parameter | Typical Range |

| Material Thickness | 0.2 – 2.0 mm |

| Coil Width | Max 2000 mm |

| Coil Weight | ≤ 15 Tons |

| Coil Inner Diameter | Φ450 mm – Φ550 mm

(customizable by the buyer) |

| Coil Outer Diameter | Max Φ 2000 mm |

| Line Speed | ≤ 80 m/min |

| Sheet Length Accuracy | ±0.5 mm |

| Cutting Type | Hydraulic |

| Leveling system | 7 rollers

(Adjustable and expandable based on product quality requirements and customer application) |

| Power | 380 Volt, 3 phase, 4 lines, 50Hz |

Technical Parameter:

|

No |

Name |

Unit |

Parameter |

|

1 |

Control model |

|

PLC frequency control |

|

2 |

Applied to |

|

Carbon steel,GI , PPGI and others |

|

3 |

Thickness |

mm |

0.3-3.0 |

|

4 |

Width |

mm |

1500 |

|

5 |

ID |

mm |

Φ480-520 |

|

6 |

OD |

mm |

≤1400 |

|

7 |

Coil weight |

Ton |

≤20 |

|

8 |

Diameter of leveling roller |

mm |

65 |

|

9 |

Distance of leveling rollers |

mm |

70 |

|

10 |

Number of leveling rollers |

|

19 |

|

11 |

Material of leveling roller |

|

GCr15 |

|

12 |

Material of cutter blade |

|

6CrW2Si |

|

13 |

Speed |

m/min |

≤60 |

|

14 |

Direction of feed material |

|

from right to left |

|

15 |

Length tolerance |

|

L=2m≤±0.5 |

|

16 |

Diagonal tolerance |

|

L=2m≤±1 mm |

|

17 |

Power |

|

380V/3PH/50HZ (customized) |

Technological process :

Coil car→uncoiling→straightening→shearing machine→stacking and piling system