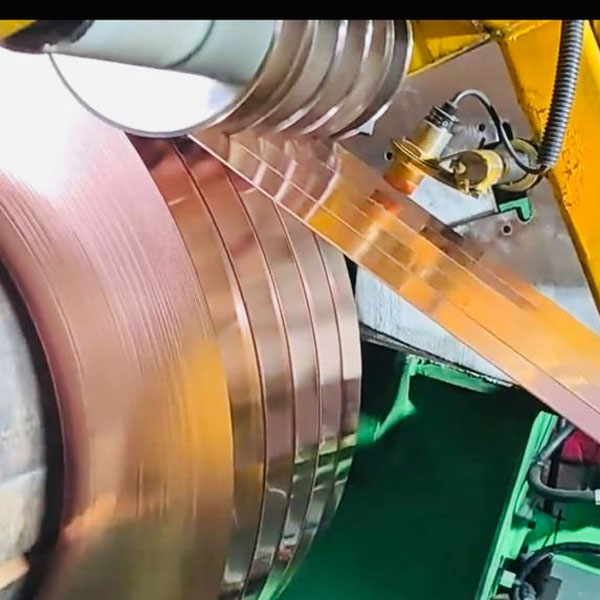

Slitting lines for light gauge

light gauge slitting lines are a game-changer in the metal processing industry. Their precision, versatility, and speed make them a must-have tool for any manufacturer working with thin materials. Whether you are in the automotive industry or the construction sector, investing in a light gauge slitting line will undoubtedly revolutionize your production process and elevate your business to new heights of success.

Main technical parameters:

|

Steel coil parameters |

Material

|

Cold roll and galvanized steel |

|

Tensile strength |

δb≤450Mpa |

|

|

Steel thickness

|

0.3– 2 mm |

|

|

Steel width |

500-1650(Max) |

|

|

Steel coil I.D |

φ480-520 mm |

|

|

Steel coil O.D |

φ1600mm(Max) |

|

|

Steel coil weight |

15T(Max) |

|

|

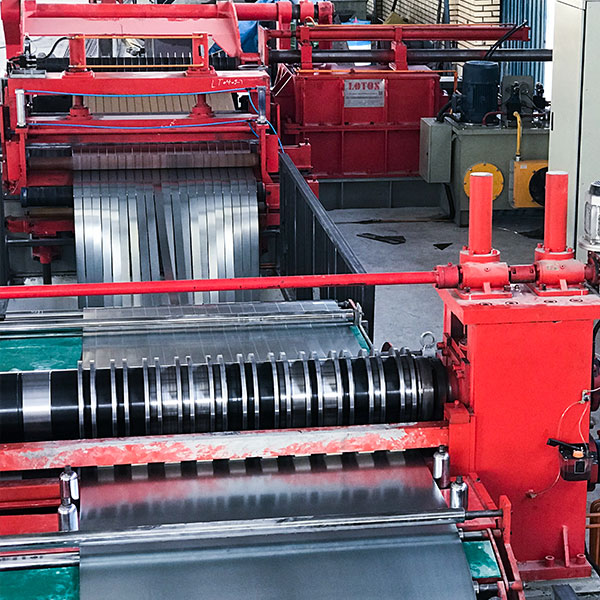

Slitter parameters |

knife pivot diameter |

Ф200 mm |

|

Knife pivot material |

40Cr |

|

|

Blades specification |

Φ340mmXφ200mmX10mm |

|

|

Blade material |

6CrW2Si |

|

|

Slit parameter |

Max slit quantity |

30 pcs (0.3mm) |

|

Width precision |

≤±0.05mm/2M |

|

|

Other parameters |

Power |

380V/50Hz/3Ph |

|

Line speed |

0-120m/min |

|

|

Capacity |

230 Kw |

|

|

Whole line Dimension |

23m(L)X10m(W) |

|

|

Operator needed |

1 mechanical engineer ,2 common workers |

|

|

Line direction |

From right to left(Face to machine) |

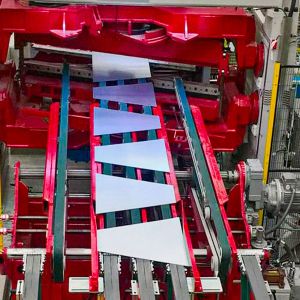

Overflow:

From right to left are: Entry coil car→Decoiler →Press and pinch device→Hydraulic cutter→Looper 1→Side guide device→ Slitter→Scrap winder→Looper 2→Tension stand →Recoielr→Exit coil car