Lines

LOTOSSlitting Company provides high-precision slitting lines designed for efficient coil processing, durability, and consistent quality output.

Electric resistance welding tube mill is used For low-pressure fluid transmission, machinery manufacturing, electric power engineering, etc.

FFX Technology for tube mill lines represents a significant advancement in the machinery and automation used in tube production.

Direct Square Welded Pipe Line is equipped with high-frequency welding equipment for producing square rectangular and irregular pipes.

API pipe tube mill lines designed to meet the rigorous demands of the oil, gas, and petrochemical industries.

Our Products

High-Speed Slitting Line

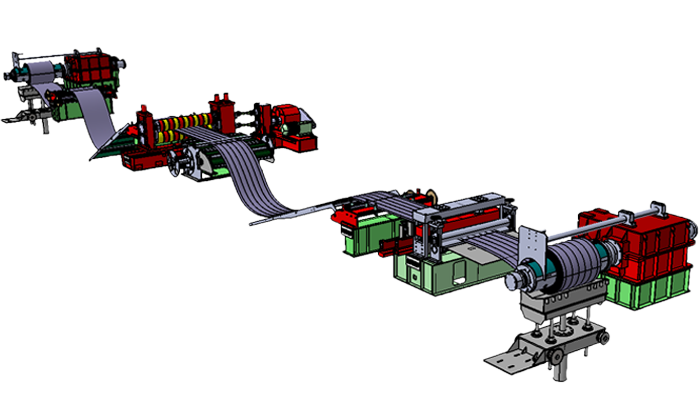

LOTOS Slitting Line Machines are engineered to provide high-precision coil slitting, efficient recoiling, and superior edge quality across a wide range of materials and thicknesses. With processing capacities from 0.2 mm up to 25 mm thickness and coil widths up to 2000 mm, our slitting lines deliver tailored solutions for light, medium, and heavy-duty applications in industries such as construction, automotive, appliances, and steel service centers. Depending on production demands, we offer high-speed slitting heads, Standard Knife Change System, precision tension control, and advanced recoiling units, ensuring optimal coil quality, efficiency, and cost-effectiveness.

Why Choose Lotosslitting’s High-Speed Slitting Line?

- Superior Precision and Quality

State-of-the-art slitter heads ensure clean and accurate cuts with minimal burrs, producing slit coils that meet strict international quality standards.

- High-Speed and Maximum Productivity

Engineered for fast and continuous operation, our lines increase throughput without sacrificing precision or surface quality.

- Durability and Reliability

Constructed with premium-grade materials and advanced mechanical design, our slitting lines guarantee stable performance and extended service life under demanding workloads.

- Customized Solutions

Every production process is unique. We provide tailor-made slitting solutions to match specific coil widths, thicknesses, materials, and production capacities — from standard configurations to specialized designs.

Advanced Line Configuration

LOTOS high-speed slitting lines deliver both excellent strip surface quality and optimized efficiency through precision-designed machines and advanced automation systems. The complete line consists of:

- Coil Loading Car – Safely transfers the coil to the decoiler.

- Uncoiler – Holds and unwinds the master coil with stable, tension-free control.

- Leveling Unit – Flattens and aligns the strip for precise cutting.

- Looper 1 – Maintains continuous flow and compensates for speed variations.

- Side Guide Device – Precisely aligns material before slitting.

- Slitting Unit – High-speed rotary knives for accurate longitudinal cutting.

- Scrap Winder – Collects and rewinds edge trims.

- Looper 2 – Balances feeding between slitter and recoiler.

- Tension & Separator Station – Applies controlled back tension and separates strips for perfect recoiling.

- Recoiler – Rewinds slit strips into uniform, tightly wound coils.

- Coil Discharge Car – Transfers finished coils quickly and safely.

- Hydraulic System – Powers coil handling, knife adjustment, and tension control.

- Pneumatic System – Operates air-powered actuators and clamps.

- Electric Control System – Centralized automation for monitoring, adjustments, and high-speed control.

Our Commitment to Global Quality

At Lotosslitting, quality is our foundation. Every high-speed slitting line undergoes strict performance testing and international quality inspections before delivery, guaranteeing reliability, safety, and long-term durability. With comprehensive warranties and professional after-sales support, we are your trusted partner in coil processing excellence worldwide.

.