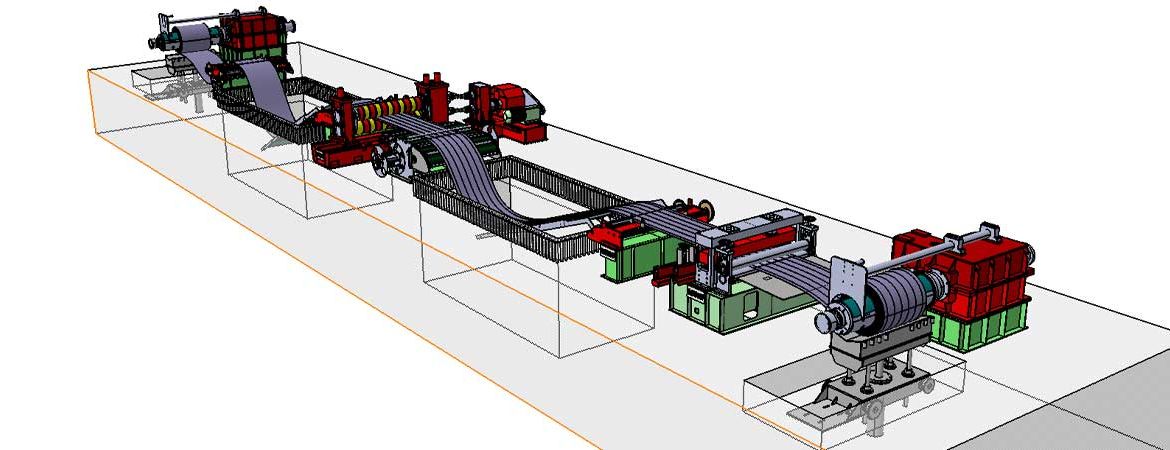

High Speed Steel Coil Slitting Line Manufacturer

A foundation for a high speed slitting line is a critical civil and structural system designed to support the machine’s static weight, dynamic loads, and operational precision under continuous high speed conditions. In modern coil processing facilities, the foundation directly influences line stability, cutting accuracy, vibration control, and long term equipment reliability. For advanced slitting lines supplied by lotosslitting, foundation design is considered an essential part of the overall engineering solution rather than a simple construction task.

Purpose of a High Speed Slitting Line Foundation

High speed slitting lines operate at elevated line speeds and process heavy steel coils, generating substantial dynamic forces during acceleration, deceleration, tension control, and slitting operations. The foundation must fulfill several key purposes:

Safely support the total machine and coil load

Absorb and dissipate vibration generated at high speeds

Maintain precise alignment of all mechanical components

Prevent long term settlement or structural deformation

Ensure safe and stable operation over the machine’s service life

Without a properly engineered foundation, even the most advanced slitting line cannot achieve its designed performance or accuracy.

Structural Composition of the Foundation

The foundation of a high speed slitting line is typically constructed from reinforced concrete with high compressive strength. Its structure generally includes:

Main foundation blocks beneath major equipment such as the uncoiler, slitter head, recoiler, and tension stations

Connecting beams or slabs to ensure load distribution and rigidity

Anchor bolt systems precisely positioned to fix machine bases

Embedded steel plates or sleeves to enhance load transfer

The thickness, reinforcement layout, and concrete grade are determined based on machine weight, coil capacity, line speed, and local soil conditions.

Load and Vibration Considerations

High-speed slitting lines generate both static and dynamic loads. Static loads come from the machine frame and coils, while dynamic loads are produced by rotating components, strip tension variation, and rapid speed changes.

A properly designed foundation must:

Resist cyclic fatigue caused by continuous vibration

Minimize resonance that can affect slitting accuracy

Isolate vibration to protect surrounding equipment and structures

In many high speed applications, vibration damping measures and increased foundation mass are incorporated to ensure stable operation.

Precision and Alignment Requirements

Precision is a defining requirement for slitting lines. Even minimal foundation movement can lead to misalignment of the slitter head, arbor shafts, and recoilers, resulting in poor strip edge quality or blade wear.

For this reason, the foundation must provide:

Excellent flatness and level tolerance

High rigidity to prevent micro-movement

Long term dimensional stability

Accurate foundation execution ensures that the machine maintains alignment throughout its operational life.

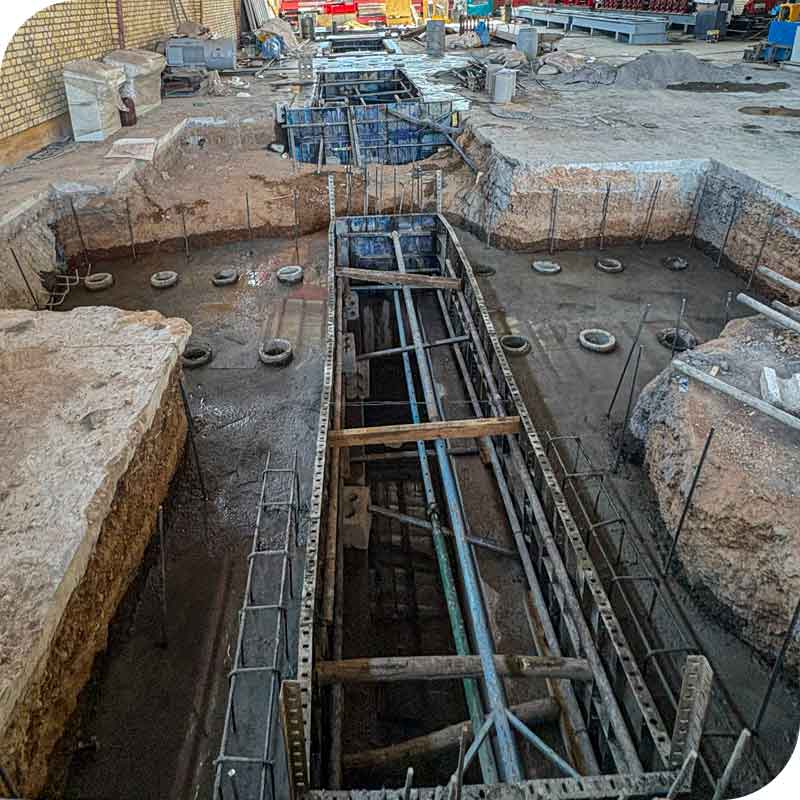

Installation and Civil Engineering Coordination

Foundation construction must be closely coordinated with machine layout drawings and installation plans. This includes:

Exact positioning of anchor bolts

Pre planned cable trenches and hydraulic pits

Adequate space for maintenance access

Proper curing time before machine installation

Professional coordination between civil engineers and machine suppliers is essential to avoid costly installation delays or rework.

Importance of Proper Foundation Design

A high speed slitting line foundation is not a generic concrete base; it is a precision-engineered structure that directly affects production efficiency, safety, and product quality. Investing in a correctly designed and executed foundation reduces downtime, extends machine lifespan, and ensures the slitting line operates at its intended speed and accuracy.

Conclusion

The foundation for a high speed slitting line is a fundamental element of successful coil processing operations. By supporting heavy loads, controlling vibration, and preserving mechanical precision, it enables high performance slitting under demanding industrial conditions. For modern high speed slitting systems, foundation engineering should always be treated as an integral part of the overall line design.

FAQ :

High speed slitting lines generate significant vibration and dynamic loads. A dedicated foundation absorbs these forces, prevents machine movement, maintains alignment of critical components, and ensures consistent slitting accuracy and long equipment life.

Most high speed slitting line foundations are constructed from high strength reinforced concrete with steel rebar, anchor bolts, and embedded plates. The concrete grade and reinforcement design depend on line speed, coil capacity, and site soil conditions.

Most high speed slitting line foundations are constructed from high strength reinforced concrete with steel rebar, anchor bolts, and embedded plates. The concrete grade and reinforcement design depend on line speed, coil capacity, and site soil conditions.

A rigid and level foundation prevents micro movements of the slitter head and recoilers. Proper foundation design ensures precise blade alignment, uniform strip width, reduced tool wear, and stable cutting performance.