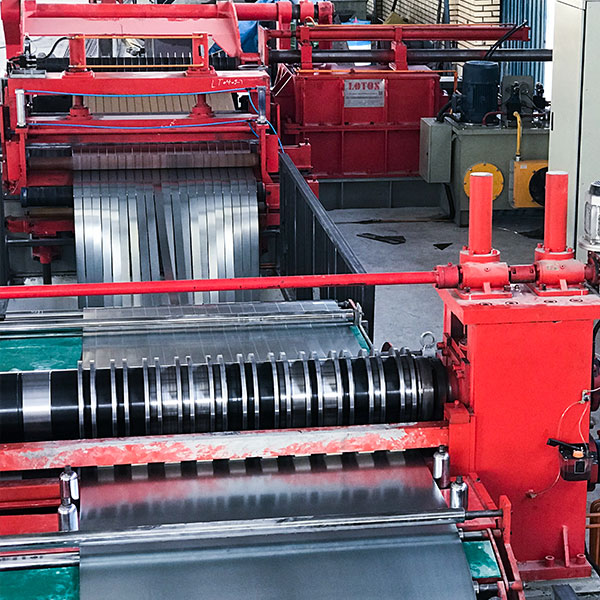

Coil Slitting Machine

One of the most impressive features of the slitting machine is its speed. Unlike manual cutting methods that are time-consuming and tedious, this machine can rapidly produce a large number of strips in a short amount of time. This not only increases productivity but also allows for faster turnaround times, giving you a competitive edge in the market. Whether you are running a small-scale operation or a large manufacturing facility, the slitting machine will undoubtedly boost your efficiency and profitability.

Furthermore, the slitting machine ensures impeccable accuracy in every cut. The blades are carefully engineered to deliver clean and precise cuts, resulting in perfectly uniform strips. This level of precision is essential for industries that require consistent and high-quality products. By eliminating human error and ensuring uniformity, the slitting Line guarantees that your materials will meet the strictest standards of excellence.

Main technical parameters:

| Steel coil parameters | Material | CRS and GI |

| Tensile strength | δb≤450Mpa,

δS≤260Mpa |

|

| Steel thickness | 0.2-3.0mm | |

| Steel width | 500-1650(Max) | |

| Steel coil I.D | φ480-520 mm | |

| Steel coil O.D | φ1800mm(Max) | |

| Steel coil weight | 20T(Max) | |

| Slitter parameters | knife pivot diameter | Ф220 mm |

| Knife pivot material | 40Cr | |

| Blades specification | Φ220mmXφ360mmX20mm | |

| Blade material | 6CrW2Si | |

| Slit parameter | Max slit quantity | 15pcs (2-3mm)

20pcs(1-2mm) 30pcs(0.3-1mm)

|

| Width precision | ≤±0.05mm/2M | |

| Other parameters | Power | 380V/50Hz/3Ph |

| Line speed | 0-120m/min | |

| Capacity | 240 Kw | |

| Whole line Dimension | 25mX8m

25m(L)X8m(W) |

|

| Operator needed | 1 mechanical engineer ,2 common workers | |

| Line direction | From right to left(Face to machine) | |

| Machine color | Red & Gray |