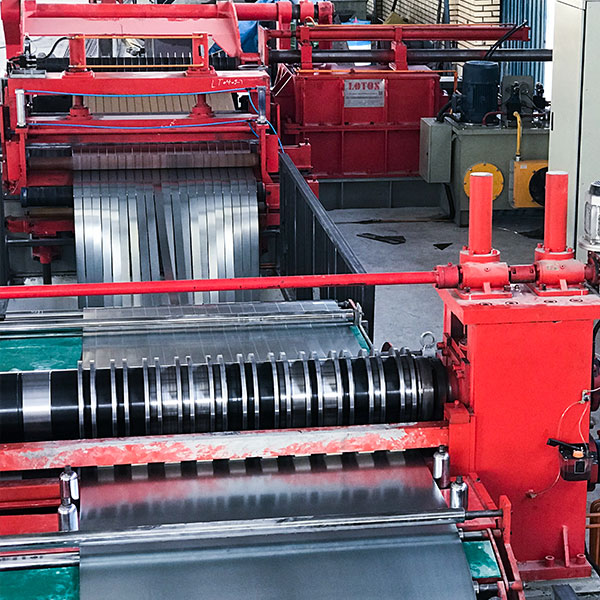

Automatic Slitting line

(1.0-6.0)×1650mm Automatic Slitting line is used for slitting the carbon steel coils and galvanized coils to prepare for the next process.Our design engineers will work to match our technology with your production needs to achieve a more efficient, more profitable operation.

Our machines are built to the highest industrial standards to ensure long lasting durability and operating efficiency. We get many repeated orders because of excellent quality & good after sales services.

automatic steel sheet slitting

The 1.0-6.0×1650mm Automatic Slitting Line is widely used across industries that require precision and

efficiency in coil slitting processes. In the automotive sector, it supports the manufacturing of high quality

body panels and structural components. In construction, the slitting line processes materials for roofing, framing,

and structural beams. Additionally, it plays a critical role in producing precision parts for electrical appliances and metal

furniture. Its adaptability to various materials and dimensions makes it an indispensable tool for businesses aiming to

meet diverse customer needs with consistency and reliability.

This slitting line is equipped with cutting-edge technology, including a hydraulic uncoiler, automatic tension control, and high-precision cutting blades. These features enable clean, burr-free cuts while maintaining material integrity. The automatic recoiler streamlines the coiling process, minimizing downtime and maximizing output. Additionally, the robust design and user-friendly interface ensure reliable operation and ease of use, even in high-volume production environments.

Coil Slitting Line Manufacturer

Choosing the 1.0-6.0×1650mm Automatic Slitting Line means investing in cutting edge technology that enhances

production speed, accuracy, and overall quality. This slitting line is designed to handle demanding workloads, ensuring

seamless operation even in high capacity environments. With its energy efficient design and low maintenance requirements, it provides acost effective solution for modern metalworking needs. By incorporating this machine into your operations,

you can achieve higher productivity, reduce waste, and deliver superior results that meet the highest industry standards